April 20, 2017

Centrifugal Air Compressors 101

SHARE THIS POST

Centrifugal air compressors are a critical part of manufacturing operations. Their efficient operation delivers high quantities of compressed air for several applications.

What Is a Centrifugal Air Compressor?

Centrifugal compressors are a type of dynamic compressor that produce large volumes of compressed air efficiently. This equipment compresses and cools the air that flows through the unit using centrifugal force. As a result, you can use a relatively small machine to generate large quantities of pressurized air.

These air compressors use a radial design and work at a constant pressure. External factors such as inlet temperature change can affect the dynamic compressor’s performance. This setup is different than displacement compressors that work at a constant flow.

Centrifugal compressors are two-stage or three-stage. Three-stage compressors allow easier temperature and moisture control after each stage to achieve an 8-to-1 pressure rise.

How Do Centrifugal Air Compressors Work?

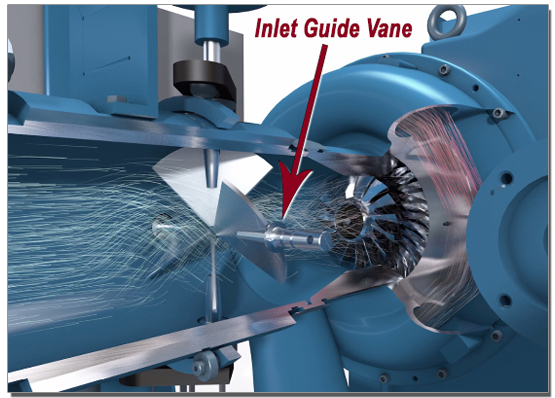

Centrifugal air compressors are dynamically engineered compressors that use rotating elements called impellers. Incoming, low-velocity air or gas reaches an inlet guide vane that automatically adjusts itself to changes in system demand, as shown in the picture. This vane regulates the incoming stream as it flows toward the first stage impeller with a “pre-swirl” effect. These impellers spin at a high rate of speed, accelerating the air or gas while pushing it toward the center of the machine by centrifugal force, hence, the name centrifugal compressor.

The ambient air or gas is then forced through a diffuser, which is a much smaller area. The diffuser’s job is to convert kinetic energy (high velocity) of the air or gas into pressure by gradually slowing (diffusing) the velocity. This progression of speeding the air up and then slowing it down causes the pressure to increase. Different applications call for different pressures. When more pressure is required, a number of different stages can be arranged in a series to achieve the necessary pressure increases.

The pressurized air then flows through an intercooler, causing the moisture in the air to condense and separate from the lower-velocity, cooled air. The separated condensate is removed through a drain valve allowing the cooled air to exit the intercooler and travel into an inlet duct for the next stage of compression, in which the entire process is repeated. From there, the compressed air or gas moves to an aftercooler where it is cooled and any remaining moisture is removed.

Centrifugal Air Compressor Applications

Centrifugal air compressors are ideal for applications that require oil-free air. The compressor assembly and centrifugal compressor gearbox are integrated and isolated from the air path by buffered seals. This highly efficient process concludes with a steady supply of exceptionally clean, oil-free air that’s ready to power a wide array of industrial applications, all while giving manufacturers the peace of mind of lower maintenance costs and less downtime.

Since they do not use oil, centrifugal compressors are one of the most efficient ways to get compressed air. As centrifugal compressors have a continuous airflow through multiple stages, they perform best when used for high-capacity applications at 200 horsepower or higher.

Centrifugal air compressors can supply compressed air to pneumatic tools, conveyors, static pressure valves and similar equipment. Air separation is another application of air compressors, as they can compress nitrogen and oxygen gases.

Common industrial applications for centrifugal air compressors include:

- Food and beverage

- Textiles

- Petrochemical

- Oil refinement

- Pulp and paper

- Plastics

- Electronics

- Chemical processing

- Power generation

- Wastewater treatment

Benefits of Centrifugal Air Compressors

One of the most important advantages of centrifugal air compressors is that they produce oil-free air. Compressed air directly or indirectly contacts the manufactured product. Oil-free air prevents the product from becoming contaminated, which is critical for sensitive applications like food and beverage, pharmaceutical and technology. Since oil-free systems use less oil, they are also easier to maintain and more environmentally conscious.

Dynamic compressors are highly efficient. Since the impellers match the required airflow and pressure, these compressors use less energy to pressurize large volumes of air. Energy efficiency leads to long-term cost savings from reduced utility usage and maintenance.

Contact Us to Order Products or Schedule a Repair or Maintenance Service

C.H. Reed offers several compressed air systems that increase product quality, energy efficiency and operational productivity. We also provide planned maintenance programs and 24/7 repair services to keep your compressors functional.

If you would like to gain more insight into how centrifugal air compressors operate and the benefits they provide for a variety of different applications, contact C.H. Reed today to speak with a centrifugal compressed air specialist.

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…