May 3, 2022

Centralized Vacuum Pumps vs Point of Use Vacuum Pumps

SHARE THIS POST

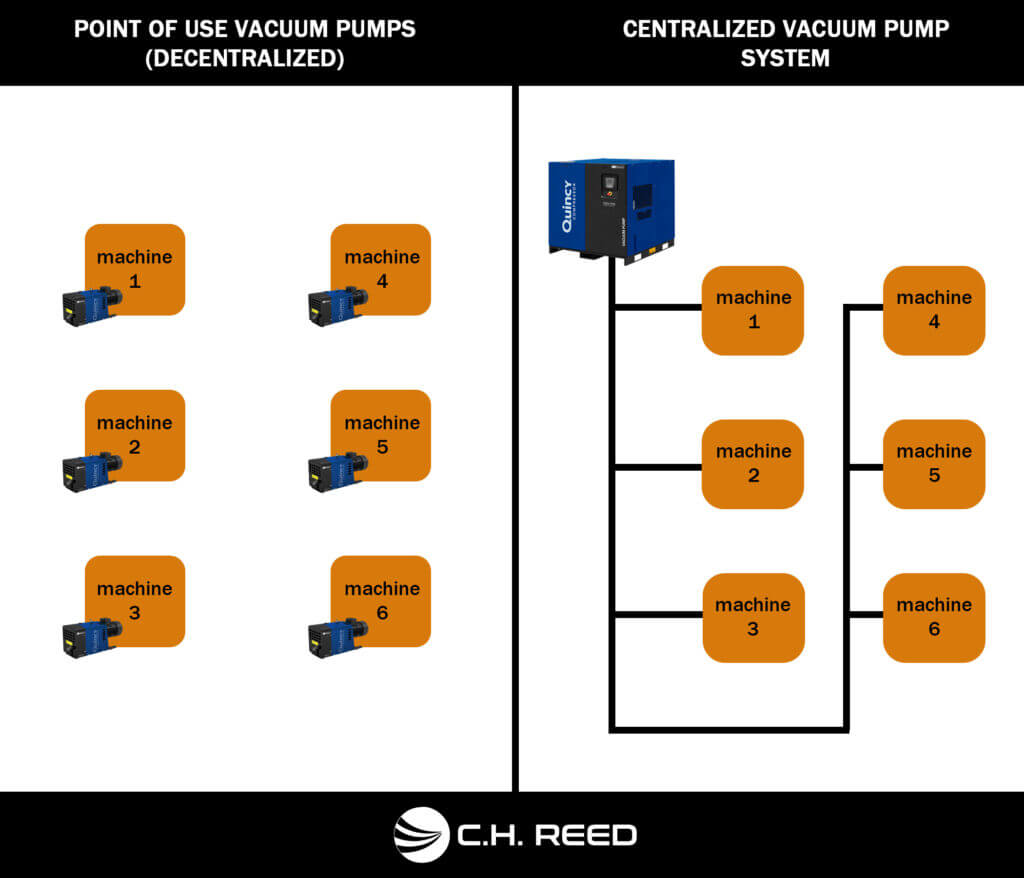

Vacuum pumps are industrial machines that remove air and gas molecules from a confined space, creating a vacuum effect that helps complete a given task. Vacuum pumps help in different holding, lifting, and moving applications, to forming, shaping, preserving, and clean environment applications. More and more manufacturing companies these days are making the switch from “point-of-use” vacuum pumps to centralized vacuum pump systems that deliver vacuum to their processes, equipment, and applications.

What are Point of Use Vacuum Pumps?

Point of use, or decentralized vacuum pumps, are individual pumps that are dedicated to a piece of equipment or machinery with the sole purpose of producing vacuum for that specific application or process. New machinery often comes as a packaged deal, with a dedicated vacuum pump included. An example of this might be a large CNC milling machine with an integrated vacuum pump that provides clamping and suction for holding and cutting parts.

What are Centralized Vacuum Pumps?

A centralized vacuum pump system is one or several vacuum pumps that feed all the facility’s equipment that require vacuum. Generally, the more equipment a facility has that calls for vacuum, the more economical a central system will be compared to point of use pumps for each piece of equipment. However, this is only a rule of thumb, and it is greatly recommended to consult with compressed air/vacuum experts to evaluate your facility’s demand and other parameters that need to be considered.

Benefits of Central Vacuum Systems vs Point of Use Vacuum Pumps:

Depending on the application, centralized vacuum pump systems deliver many advantages over point of use or decentralized pumps:

- Energy Savings: A decentralized vacuum pump system installed directly at the point of use always operates at full power, which is less efficient than just having one pump perform the work. This consumes a lot of energy. Centralized vacuum systems, on the other hand, are controlled on a demand-driven basis. Central systems often use advancements in vacuum and compressed air technology, like variable frequency drives, which allow for finer-tuned performance adjustments where the system only generates as much vacuum as needed at that exact moment. This results in greater energy saving potential compared to point of use pumps. The centralized vacuum pump energy savings when utilizing an oil-water heat exchanger depend on factors such as operating conditions and timely preventive maintenance. You can also recover and reuse this energy, minimizing costly waste.

- Ease of Use: Once installed, centralized vacuum pump systems are very easy to use with automatic start and stop functionalities.

- Simple Expansion: On-demand vacuum with centralized systems offers much more flexibility, making expansions and adding additional vacuum modules much easier. An example being a facility adding a new packaging line.

- Maintenance Cost/Time Reductions: Centralized vacuum systems are much easier to maintain compared to point of use pumps. The fact that central systems only use one or a few pumps to feed the entire plant means there are much fewer pumps to service vs. individual pumps at every piece of equipment. Centralized systems are also much more accessible as they are usually installed in a dedicated room or area. This means maintenance personnel doesn’t even have to go into the production area or interrupt operations to service the pumps.

- Continuous, Uninterrupted Operations and Increased Productivity: Many centralized vacuum systems include a backup pump that comes online automatically should a primary pump fail. This allows production or packaging to continue uninterrupted while maintenance and service work is performed on the primary pump. With point of use pumps, the entire operation associated with the downed pump would come to a halt so maintenance could be performed, or the pump is switched out.

- Increased Reliability and Lifetime: When you have point of use pumps, they are always running at full power. With a demand-driven, centralized system, operating hours are much lower with consistent pressures and less strain. This increases the longevity and reliability of the pumps.

- Worker Safety & Comfort: By removing vacuum pumps from immediate work areas, noise levels and heat generated by the pumps and motors are drastically reduced. Also, if the point of use pump is oil-lubricated or water-cooled, centralizing the system removes potentially hazardous spills that could cause a worker to slip. This also makes for a cleaner working environment for employees since the maintenance of pumps is performed outside of the production areas.

- Heat Recovery Opportunities: By using an oil-water heat exchanger, an estimated 50-70% of a motor’s energy consumption can be recovered and reused. Also, since the heat from the pumps is no longer in the production or packaging area (which is often a cooled area) your facility’s HVAC system won’t have to keep up with cooling the room down from the excess heat, which will save on utility costs.

Central Vacuum System Pros and Cons

Specific examples of the many central vacuum pump system benefits include:

- High Uptime: These systems include a standby vacuum module to safeguard against shutdowns and keep the operation running efficiently in all conditions.

- Noise Reduction: Centralized pumps are often installed in a separate utility room or other areas away from workers and visitors, helping to create a quieter environment.

- Longevity: These pumps operate on a demand-driven basis. Since they only produce the vacuum when needed, there is less strain on the equipment’s parts and components.

- Even Workload Distribution: The configuration of central vacuum pump systems spreads the workload across multiple modules. This setup contributes to a longer life span and reduces maintenance and repair costs.

Some potential drawbacks include:

- Lack of Power: Since they’re not application-specific, a centralized vacuum may deliver insufficient power for certain tasks. If different vacuum levels are required, the pump typically pulls from the lowest level.

- Complexity: These systems require extensive piping networks, controls and other components and accessories to install and operate, making them more challenging to set up initially.

- High Transition Costs: Moving from a decentralized to a centralized vacuum pump system can create a significant upfront investment for a business. But, increased energy efficiencies can makeup for those costs in the long run.

Applications Where Central Vacuum Systems Are Common

There are many different industries and applications that could potentially benefit from a centralized vacuum pump system. Generally, when a facility has several point of use vacuum pumps that feed different pieces of equipment during their processes, they are more likely to experience the benefits of a centralized system. Common applications include:

- Vacuum Packaging: These systems can remove air from food packaging, helping to protect the product from the damaging effects of oxygen.

- Canning: These vacuum pumps are essential equipment in high-volume canning production lines.

- Glass Bottle & Container Manufacturing: Vacuum pumps for glass bottles and jars help ensure secure contents storage.

- Material Handling Quincy Central Vacuum Pump: These pumps power vacuum lifters when elevating and handling loads in a material handling environment.

- Woodworking and CNC Routing: Professional woodworking shops can use central vacuum systems to optimize performance in processes like laminating and veneering, as well as for CNC routing applications.

- Medical Vacuum Supply: Medical vacuum pump systems generate the negative pressure environment required for suction in various procedures.

To summarize, a centralized vacuum system can offer many benefits compared to point of use pumps. From substantial energy efficiency gains, increased productivity, increased reliability, maintenance cost reductions, and worker comfort. However, centralized systems are not for everyone. Expert evaluation is highly recommended prior to making commitments.

If your company would like to learn more about transitioning to a central system and need help identifying if it is the right decision, contact C.H. Reed to speak with a vacuum specialist. As a premier Quincy Compressor distribution and service center, we have the expertise and resources to help you identify the right vacuum solution for your applications.

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…