Compressed Air Treatment Equipment

The quality of your compressed air is extremely important for your business. C.H. Reed offers a wide selection of air treatment equipment to combat particles, moisture, and oil. From refrigerated and desiccant dryers to mist eliminators, flow controllers, nitrogen generators, process chillers and filters, C.H. Reed provides the latest compressed air treatment equipment and technologies that reduce operating costs, increase performance, and enhance system reliability.

Compressed Air Dryers

Refrigerated compressed air dryers remove water vapor and contaminants from a compressed air stream. They use a refrigeration compressor to cool the air to approximately 35 -40 degrees; a temperature where the moisture condenses and gets drained off. A heat exchanger is used to pre-cool the incoming air and re-heat the outgoing air as it leaves the dryer. The three main types of refrigerated air dryers are cycling, non-cycling, and high temp. Refrigerated air dryers are used in most general-purpose industrial compressed air applications because of their relatively low up-front, operating, and maintenance costs.

Desiccant compressed air dryers purify compressed air by absorbing moisture onto a porous desiccant material. These dryers produce low dew points, sometimes as low as -100, so they are ideal in very cold conditions where applications need extremely dry air. The most common dew point rating for desiccant dryers is -40. While this level may be needed for sensitive processes or equipment, it is not often needed in general manufacturing (unless the pipes are exposed to freezing temperatures.)

With a variety of different refrigerated and desiccant air dryers available from Quincy Compressor, Hankison, BEKO, Nano, and ZEKS, C.H. Reed can work with you to identify the best option for your specific needs or equipment parts.

Nitrogen Generation Systems

Many different commercial, industrial, and manufacturing industries use nitrogen, a dry and inert gas, to improve the quality of a product, improve operational processes, or as a combustion-prevention safety measure. Traditionally, nitrogen would get delivered via a third party in a liquid or bottled form, where users are responsible for several hidden costs (rentals, refills, delivery charges, processing charges, environmental levy charge, etc.) Not to mention, storing nitrogen in liquid and bottled form is a safety hazard.

On-site nitrogen generation systems use your facility’s compressed air to deliver a continuous supply of high purity nitrogen; fulfilling nitrogen demands when you need it and under complete control. This allows users to generate as much or as little nitrogen as needed at a fraction of the cost from an external supplier. Nano nitrogen generation systems are safe, reliable, easy to install, and very easy to maintain. To learn more about how nitrogen generation systems work, click on the image below:

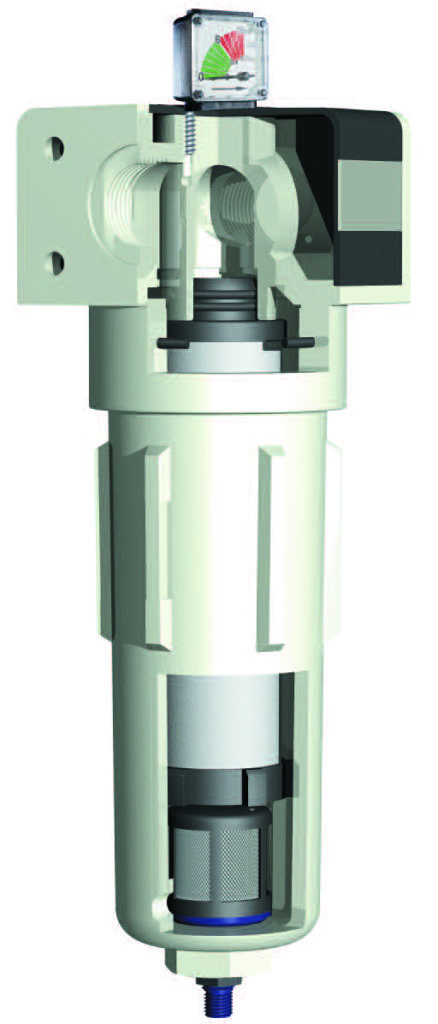

Compressed Air Filtration

Your compressed air is contaminated! Compressed air filters are used to remove contaminates from your compressed air. Your air compressor naturally produces oils, aerosols, vapors, and other wear metals in the air stream; polluting the air that feeds your plant. This can cause potential damage to the equipment that relies on that compressed air and possibly the product(s) you produce. Incorporating the correct compressed air filter on your system can eliminate the unwanted contaminates, particulates, aerosols, and vapors.

There are more than a few consequences of not changing your compressed air filters at regular intervals. On top of increased pressure drops and decreased energy efficiency, dirty or damaged

filters can cause downtime, damaged or re-worked products, corrosion within your system, destroyed desiccant, damaged tools, pulsing air demands, and temperature fluctuations.

There are many different types of compressed air filters out there; from general purpose, particulate, and coalescing filters to pre-filtration, charcoal vapor removal, reverse flow filters, and mist eliminators. When every dollar counts, it is important to make sure you choose the right filters for your compressed air system. You can rely on C.H. Reed’s decades of compressed air industry experience to help with all your compressed air filtration needs. Be sure to check out this article to learn more about compressed air filter elements.

Oil Water Separators

Every year, compressed air systems produce thousands of gallons of oil-contaminated condensate. Collecting, storing, and properly disposing this oily waste is both messy and expensive. Oil water separators simply remove the oils and other contaminants from your compressed air system’s condensate allowing you to dispose of it safely; plus, the environment will thank you.

All oil water separators work on the same underlying principle of absorption. By directing the system’s condensate into an oil water separator, the oil gets collected on some type of filtration media so the remaining water can be disposed of safely and in compliance with environmental regulations. With industry leading partners like NANO, Quincy Compressor, Summit, and Jorc, C.H. Reed has the oil water separation solution that can take care of oily compressor condensate in an environmentally friendly manner that exceeds state regulations.

Rely on C.H. Reed to Increase the Quality of your Compressed Air

For those in Pennsylvania, Ohio, Maryland, Delaware, Virginia, West Virginia, and the general Mid-Atlantic region, we offer local sales and service for all air treatment solutions to the following locations and surrounding areas:

Contact our team of experts today!

"*" indicates required fields