November 29, 2018

The Importance of Changing Compressed Air Filter Elements

SHARE THIS POST

The Importance of Changing Compressed Air Filter Elements

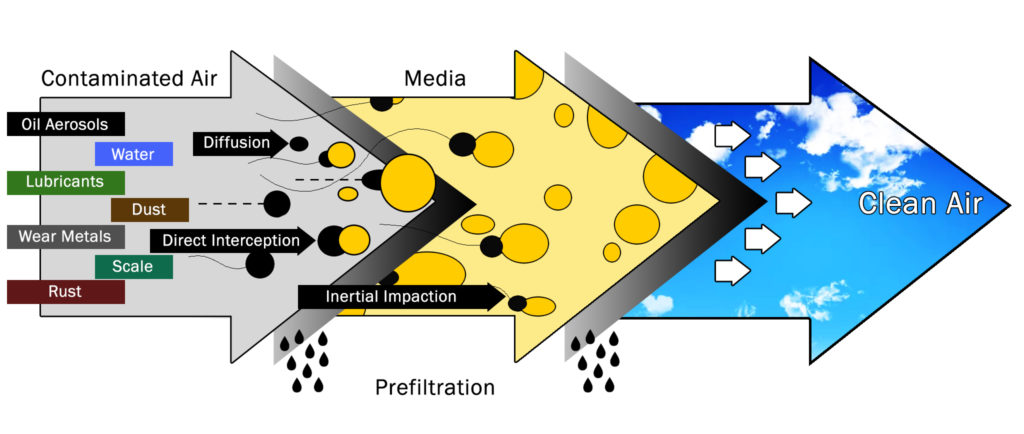

Changing compressed air filter elements at regular intervals is vital because your compressed air is contaminated! Airborne water vapor and dust are drawn into your compressor intake. Your air compressor adds oil, aerosols, vapors, and other wear metals. Compressed air piping can add rust and scale, depending on the type of pipe you use. When the compressor is in operation, the filtration media in the filter element is constantly being blasted by these dirt particles and contaminates. This will eventually lead to the filter media’s demise, rendering it useless, while contamination gets carried downstream in your compressed air system.

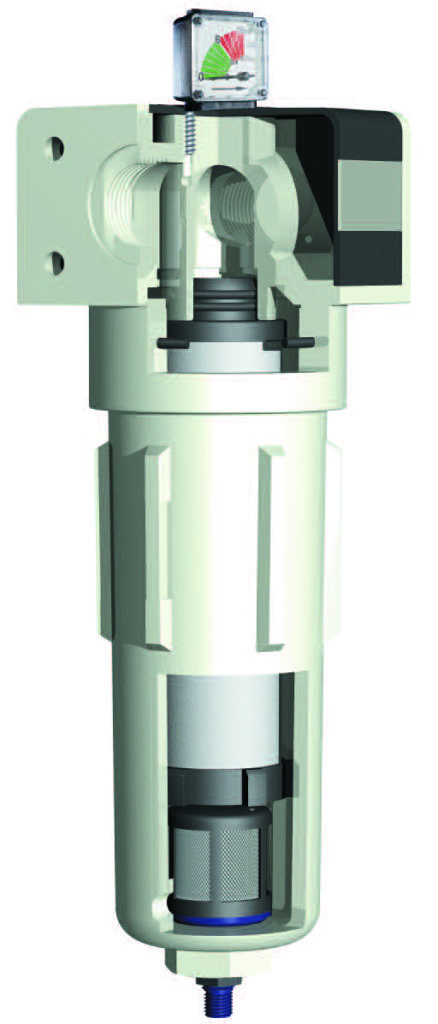

Dirty, damaged filters increase pressure drop, which in turn, decreases the energy efficiency of the compressed air system. C.H. Reed advises that you replace your compressed air filter elements when pressure drop exceeds 2 to 3 psi OR annually; whichever comes first.

What are the consequences of not changing compressed air filter elements?

On top of increased pressure drops and decreased energy efficiencies, dirty and damaged filters can cause other problems that compromise your compressed air system:

- Downtime ($$$)

- Damaged, spoiled, and / or re-worked products

- Corrosion within your compressed air system

- Destroyed desiccant

- Damaged valves, air motors, pneumatic tools, machinery, and other equipment that operate with compressed air

- Pulsing air demands

- Temperature variations

Real-Life Example of How Dirty or Damaged Compressed Air Filters Can Cost You a lot of Money

A 100 HP compressed air system operating continuously at a cost of $0.08/kWh has annual energy costs of $63,232. With a dirty or damaged coalescing filter (not changed at regular intervals), the pressure drop across the filter could increase to as much as 6 psi (versus 2 psi when clean), resulting in a need for an increase in system pressure. The pressure drop of 4 psi above the normal 2 psi accounts for 2% of the system’s annual energy costs, or nearly $1,265 per year. At $0.12/kWh, this would be $1,897 per year, per filter. A 3-filter system could cost you $5,691 per year.

Annotation Addendum – C.H. Reed’s Advanced Monitoring Capabilities

With C.H. Reed’s advanced control and monitoring capabilities, a 3 psi differential pressure switch can be installed on almost any compressed air filter housing. The switch can be monitored by Quincy’s ICONS system that is standard on most premium and industrial grade Quincy air compressors, or can be added to ANY compressed air system, regardless of brand. If the differential switch is activated, indicating a dirty compressed air filter, your plant maintenance department and the C.H. Reed service department would be notified right away.

When every dollar counts, can you afford not to change your compressed air filter elements at regular intervals? If your compressed air filters are due for replacement, C.H. Reed can help. Contact us today.

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…