February 3, 2022

Custom Unloading System for Snack Food Manufacturer

SHARE THIS POST

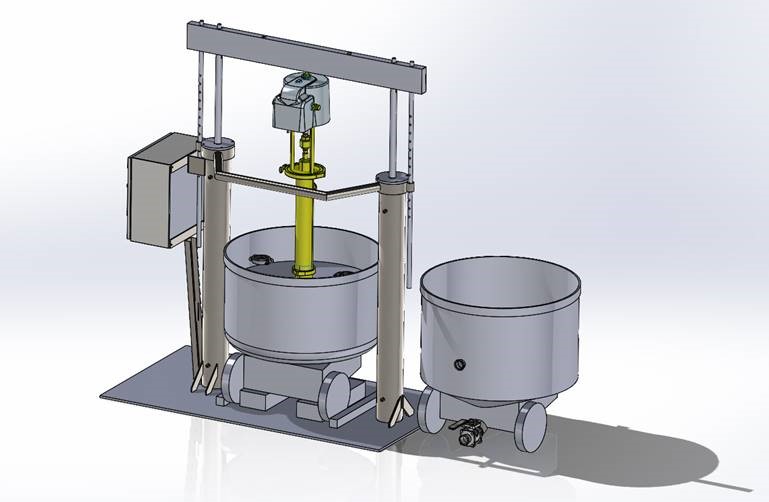

Custom Unloading System for Icing Evacuation

We recently worked with a local snack food manufacturer to address an issue regarding the evacuation of icing during one of their manufacturing processes. The main goal for this project was to eliminate as much residual material (that previously had to be manually reclaimed) after evacuating a bowl of icing into another bowl.

The Customer’s Unloading Issue

The previous unloading system was from a competitor and left an average of 200 lbs of icing in the bowl after pumping, which then had to then be manually reclaimed by hand. This was done by an operator physically having to bend over the bowl and scoop the leftover icing into the next bowl. Having to manually scoop 200 lbs of leftover material by hand is not only unsanitary, but it’s also an unsafe/repetitive task for the operator that actually resulted in several workman comp cases.

C.H. Reed’s Custom Unloading System Solution

To address these issues, our Engineered Systems Team designed a custom unloading system specific to the customer’s equipment. The new system utilized an air-powered 3″ Graco ram sanitary pump package, a custom pump platen for the customer’s specific mixing bowls being used, and integrated controls.

The ram equipment is designed to assist the loading of positive displacement pumps for extra-heavy, viscous or semi-solid materials. The priming assist is accomplished by inserting and pushing the ram plate into the open top of the icing container. This plate is pushed down into the container with a pair of double-acting pneumatic cylinders to pressurize the system. The resulting pressure assists the priming of the pump by forcing material up through a hole in the plate where the pump is located. Included with this ram are pneumatic controls that direct air pressure to both sides of the cylinder pistons for power pump priming or elevating the plate in order to change containers. Lastly, the ram plate includes a wiper seal that follows the contour of the container, keeps the container walls clean, and protects unused materials from dirt, moisture, and air.

The End Result

The previous pumping system was leaving over 200 lbs of icing that had to be hand-scooped to a new mixing bowl after evacuating. Our new custom unloading system proved to be very successful, leaving only 10 lbs of icing that has to be scooped after evacuation. This is a 95% decrease in residual material leftover after evacuation compared to their old system! The customer is very pleased with these results and is looking to add 4 more units down the road.

To see more of our sanitary pumping capabilities, check out our sanitary pumps and packages product page. Lastly, be sure to contact us for your next fluid transfer/pumping project, big or small.

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…