November 10, 2021

Electric vs Pneumatic Pumps Energy Usage Comparison

SHARE THIS POST

Industrial fluid transfer and process pumps are used to move all types of fluids with varying degrees of viscosities, from oils, inks, and paints to peanut butter and tomato paste. These pumps come in a range of sizes and capabilities with pneumatic, hydraulic, and electric options.

With continuous technological advances in electric industrial pump capabilities, including integrated automation, controls, and networking, electric pumps are rising to the top. Electric pumps help reduce pulsation, increase pump life and last longer than other pumps. They also use 5x less energy to operate compared to traditional air-operated pumps.

To understand how much money a manufacturing plant can save in their painting operating cost by switching to electric pumps and agitators, we’re sharing a Graco case study that compares electric vs pneumatic pump energy usage. Read more to learn just how much you can benefit from using electric industrial pumps.

Electric vs Pneumatic Pump: Consumption of Power vs Consumption of Air

In this brief case study, we compare the annual costs to operate electric pumps and agitators against the cost to operate air-power pneumatic pumps and agitators. Below are a few bullet points to set the stage for this painting operation example:

- A manufacturing facility has a total of 10 paint circulation pumps and 10 agitators.

- They operate one 8-hour shift per day, 5 days a week.

- They have 10 paint spray application points in their facility.

- The paint circulates 24/7/365 as the paint needs constant agitation.

- A standard rule of thumb is that 20.91 CFM of air consumption uses 1 kW of power in most air compressors.

The painting operation’s air consumption in paint circulation and paint application is as follows:

- The plant’s paint agitators have a constant air draw, consuming air 24/7.

- The plant’s pumps have a constant air draw, consuming air 24/7.

- The plant’s paint proportioners have a sporadic, valve-operated air draw, only consuming air during production.

- Air-operated regulators’ air draw is sporadic and set to hold pressure, consuming a low amount of air.

- Paint applicators have a sporadic air draw, only when spraying. They spend 45 minutes per hour spraying.

Consumption of Air in Pneumatic Pumps and Agitators

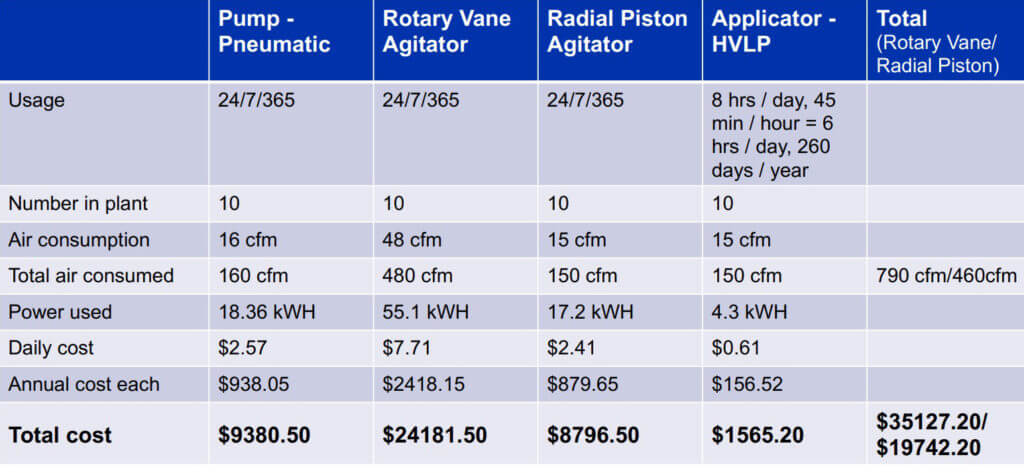

The chart below is a representation of the plant’s consumption of air and total annual energy cost for operating their painting operation. This analyzes the use of pneumatic pumps, pneumatic agitators (rotary vane and radial piston are separated to show the cost of each), and HVLP paint applicators.

Consumption of Power in Electric Pumps and Agitators

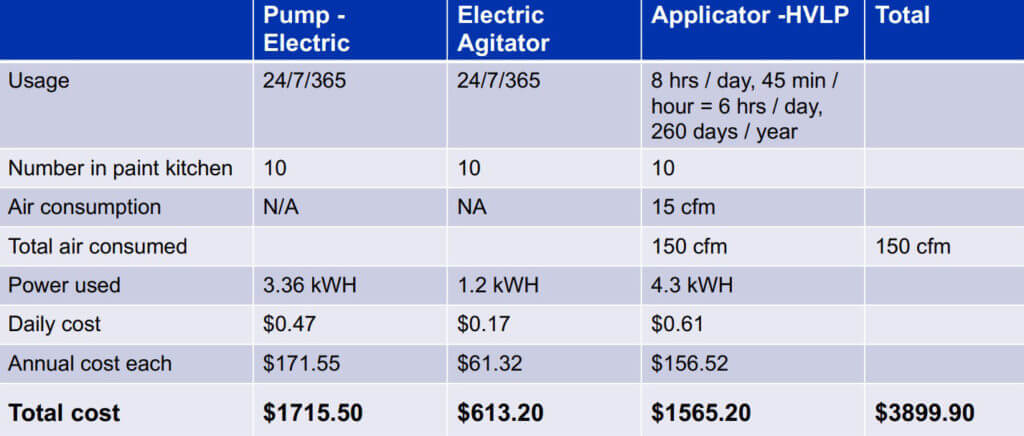

This chart is a representation of annual energy costs and consumption of power after this manufacturing plant swapped the pneumatic equipment for electric pumps and electric agitators. The paint applicators remain the same as before.

Benefits of Electric Industrial Pumps

When switching from pneumatic pumps and agitators to electric versions, this plant’s annual energy costs associated with its painting operation decreased substantially.

- If previously using rotary vane agitators (which consume more air to operate than radial piston agitators) their annual operating cost went from $35,127.20 a year to $3,899.90 a year, a savings of $31,227.30.

- If they were using radial piston agitators before, their annual operating cost would have gone from $19,742.20 to $3,899.90, a savings of $15,842.30.

Save Energy and Money With Electric Pumps

Recent technological advances of electric industrial pumps offer distinct advantages over air-powered and hydraulic pumps. A big advantage is an ability to control pressure and flow. They have less variability and offer consistent operations, fluid deliveries and spray performances, and can increase paint circulation life. Perhaps the biggest advantage is the increased energy efficiencies and cost savings, as seen in the above case study, that a manufacturing company can achieve in annual operating expenses.

If you are interested in learning more about electric industrial pump technologies, contact C.H. Reed. As an industry-leading Graco distribution and service company, we can work with you to help determine an ROI based on your current pump parameters to compare annual operating costs.

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…