June 24, 2014

Eliminating Inefficiencies in Compressed Air Systems

SHARE THIS POST

Recently, Kevin Higgins, the managing editor of Food Processing, wrote in depth about smarter, more efficient food manufacturing plants. In his article, he mentioned that in the United States, “industry is the biggest consumer of energy”, and that according to a Department of Energy Study, two-fifths of that energy “is lost to inefficient pumps, fans, compressors and other equipment”. Those energy costs aggregate annually to approximately $60 billion.

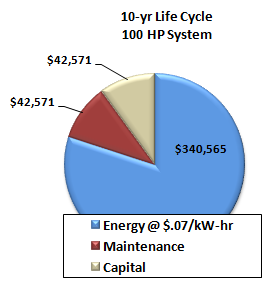

The staggering amount of wasted energy presents an opportunity for significant savings in manufacturing facilities, especially for those using compressed air systems. Compressed air is a costly utility, and energy costs account for about 80% of an air compressor’s operating costs over a 10-year life cycle. This means energy efficiency should be a major consideration when selecting an air compressor or upgrading an existing system.

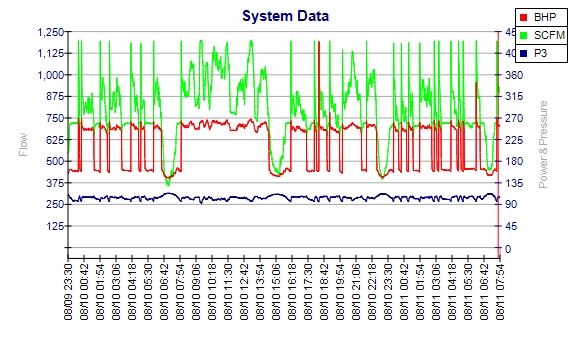

Whether you are implementing a new system or upgrading an existing one, there are a number of tools and resources available to help analyze and improve your compressed air system. By identifying the flaws of your system, you can determine the best opportunities for improving efficiency, saving money and cushioning your bottom line. One of the best tools for analyzing compressed air systems and identifying potential savings is the Quincy EQ Analyzer, a data logging system that provides a detailed analysis of a facility’s energy efficiency.

Below: An example of a data log provided by the Quincy EQ Analyzer

The award-winning Quincy EQ Analyzer (available as an iPad app) records an air system’s existing performance and proposes multiple options for system optimization. At C. H. Reed, we have used the Quincy EQ Analyzer for many of our clients to provide a baseline analysis of their compressed air system. It has helped us provide well-informed recommendations for facility managers to help them eliminate inefficiencies and take advantage of potential savings.

The award-winning Quincy EQ Analyzer (available as an iPad app) records an air system’s existing performance and proposes multiple options for system optimization. At C. H. Reed, we have used the Quincy EQ Analyzer for many of our clients to provide a baseline analysis of their compressed air system. It has helped us provide well-informed recommendations for facility managers to help them eliminate inefficiencies and take advantage of potential savings.

One such client was a manufacturer of hydroelectric power generator equipment. At this particular manufacturing facility, the existing annual operating cost of their compressed air system was $146,048. After a thorough analysis of both the supply and demand sides of their compressed air system, a projected $64,376 of annual savings was identified through a proposed system upgrade. The recommended improvements required an investment of an estimated $80,500 in new equipment and system reconfigurations, resulting in a timeline for the return on investment of approximately 15 months.

There were two recommended options for this compressed air system; either the Quincy QGV variable speed drive or the Quincy variable capacity compressor, both of which could provide dramatic energy savings. For this application, we implemented the Quincy variable capacity compressor, as it was the more economical of the two options. The Application Specialists at C. H. Reed also helped to reduce the pressure drop in the air compressor system by modifying their piping system.

To learn more about the Quincy EQ Analyzer or download the Self-Analysis Worksheet, visit Quincy’s EQ: Efficiency Quotient page.

For any other questions or comments, please leave your feedback below or contact us directly.

800.692.7216 | solutions@chreed.com

Posted by Clinton Shaffer

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…