March 19, 2020

Guide to Plural Component Metering Equipment

SHARE THIS POST

Plural component metering equipment offers numerous advantages over hand-mixing elements for use in paint spraying systems. These advantages include increased efficiency, improved accuracy and reduced costs, among others. In this guide, we’ll discuss what plural component metering equipment is, what its benefits are and why it is important.

What Is Plural Component Metering Equipment?

Plural component metering equipment automatically mixes two-component and three-component materials within a spray system, just before application. This is in contrast to manually mixing elements by hand in a piece of equipment (also known as “hot potting”) that is separate from spraying equipment.

Plural component equipment can be used for spraying materials such as:

- Protective coatings

- High-performance coatings

- Spray foam insulation

- Waterproof coatings

- Fireproofing coatings

- Two and three-component materials

Two common types of plural component metering equipment are two-component proportioners and three-component proportioners:

Two-Component Proportioners

Two-component proportioners automatically combine resin and a catalyst at a predetermined ratio. They feature a modular platform design and come with various meter options, including helical gear, spur gear and Coriolis, or positive displacement pump options. They can be used for many different types of materials.

You also have the option of configuring two manual or automatic operated spray guns, which enables you to manage each spray gun independently for improved flexibility, productivity and process control. Two-component proportioners include touchpads for user-friendly control and advanced software that provides material tracking and reporting.

Three-Component Proportioners

Automated and manual proportioners for combining three-component materials are also available. As with two-component configurations, they feature a modular color change system and can support up to 25 colors, four catalysts, and four reducers. In addition, they feature intrinsically safe fluid panels to meet safety requirements and codes, and multiple flush options are available to optimize flushing sequences and minimize waste.

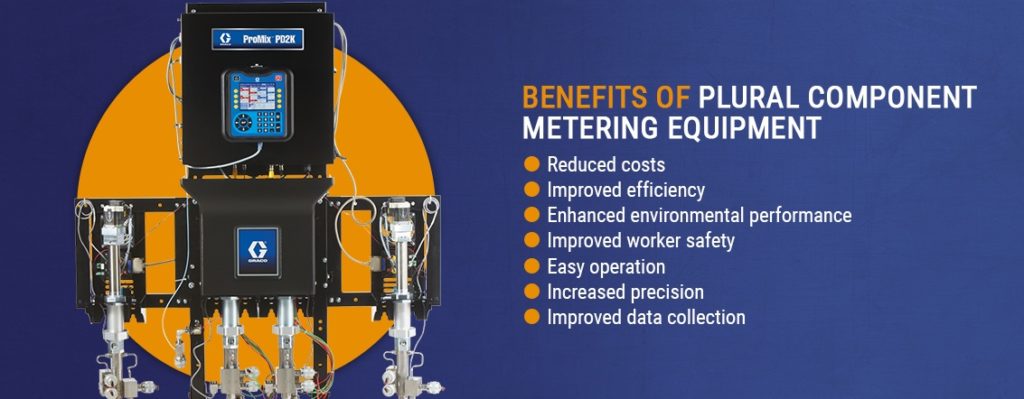

Benefits of Plural Component Metering Equipment

Plural component metering equipment can provide numerous benefits to users across a wide range of manufacturing industries. Some of these benefits include:

- Reduced costs: Mixing components in separate equipment before spraying often results in waste due to excessive mixed materials. Plural component equipment automatically mixes your materials as you apply them, so you only mix as much as you use for a given job; eliminating labor costs associated with hand-mixing.

- Improved efficiency: With plural component equipment, at the end of a job, all you need to do is flush out the sprayer and shut it down, saving you significant amounts of time compared to other mixing methods. Plural component systems can also help you achieve reduced cure times, decreasing production time.

- Enhanced environmental performance: Plural component proportioners require only small amounts of solvents for flush and reduce the emission of volatile organic compounds (VOCs). This, along with the reduction in waste, means improved environmental performance.

- Improved worker safety: Using plural component proportioners reduces potentially toxic emissions of VOCs and other substances, including potentially explosive compounds — this improves user safety, especially when working in enclosed spaces.

- Easy operation: Plural component metering equipment automates many tasks that are typically manual, which makes jobs easier and more efficient and reduces the likelihood of mistakes occurring. They are also designed to be easy and comfortable to operate.

- Increased precision: Plural component equipment uses sophisticated technology to consistently mix materials to precise ratios. This reduces mistakes and results in accurate, precise mixes that help ensure the product meets the customer’s expectations, which means fewer re-works and more satisfied customers.

- Improved data collection: This equipment uses the Internet of Things (IoT) and advanced data analytics technologies to track, analyze and report on operation and material usage. This easy access to data and reports can help you to monitor and improve your processes.

Importance of Maintaining Plural Component Metering Equipment

To get all of the benefits of plural component equipment, you need to perform regular maintenance to ensure it remains in good condition. This requires setting up a preventative maintenance program, which involves scheduling maintenance and performing it as scheduled to keep equipment in optimal condition and avoid major breakdowns.

Some of the benefits of following a preventative maintenance plan for plural component metering equipment include:

- Improved performance: Preventative maintenance helps ensure your machines continue to work correctly and efficiently. Keeping your plural component proportioners in good repair helps you to take full advantage of their capabilities and the benefits they provide.

- Fewer major repairs: A planned maintenance program helps ensure you keep up with small maintenance tasks, such as replacing worn components, before they lead to more significant, costly breakdowns. Regular maintenance checks can also reveal signs of potential future failures, enabling you to take steps to prevent them.

- Extended equipment life: When you keep up with regular maintenance, your equipment will last longer, increasing return on investment.

- Reduced downtime: Fewer major breakdowns and equipment replacements means less downtime. Unplanned downtime can put you behind schedule and cause significant financial losses. With preventative maintenance, you’ll have less downtime, and you can schedule the minimal downtime you do have.

- Improved safety: Equipment that is in good condition is safer to operate, and regular maintenance checks can help detect and correct any potential safety issues that arise before they lead to an incident.

- Reduced costs over the long term: Although preventative maintenance requires some upfront investments, it leads to reduced costs and risks in the long run. Preventative maintenance improves equipment efficiency and reduces the likelihood of potentially costly breakdowns, downtime and safety issues.

Maintenance Tips

Your preventative maintenance plan should cover all of the components necessary for keeping your plural component metering equipment in optimal condition. While this isn’t an exhaustive list, some of the maintenance that should be included in a plan include:

- Checking the power supply and voltage daily.

- Inspecting and replacing all wear items and filters according to the maintenance schedule.

- Replacing hose components regularly and when they start to become worn.

- Scheduling an annual fluid mix manifold rebuild, which includes a full inspection and cleaning and replacement of seals and o-rings.

- Scheduling an annual motor inspection and replacing motor parts as necessary.

- Keeping spare parts on hand, so you can complete any necessary maintenance tasks or repairs quickly.

Plural Component Equipment Solutions From C.H. Reed

At C.H. Reed, we offer two and three-component proportioners from top manufacturers, such as Graco Plural Component Systems, Ransburg and Binks Plural Component Systems and Nordson Plural Component Systems. We can also help you keep your plural component equipment in optimal condition through our planned and preventative maintenance programs, fluid mix manifold rebuilds and refurbishing programs.

We have locations in Hanover, Erie, Pittsburgh and Milton, Pennsylvania, as well as Cleveland, Ohio, and serve customers across Pennsylvania, Ohio, Maryland, West Virginia, Delaware, New York, Virginia, and West Virginia.

For help finding the right plural component equipment solution, and to learn more about our additional products, services, and solutions, check out our website and contact us today.

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…