August 2, 2021

Guide to Vacuum Pumps

SHARE THIS POST

Guide to Vacuum Pumps

Vacuum pumps remove gases from a confined space, creating a vacuum to complete various tasks depending on the industry or application. These systems are often used in industrial, research or manufacturing operations when a clean environment or pressures below atmospheric levels are needed.

Learn what vacuum pumps are, their types and benefits in this guide to vacuum pumps.

What Is a Vacuum Pump?

A vacuum pump is a mechanical device that removes air and gas molecules from a sealed chamber by changing high and low-pressure states. The number of particles per unit volume decreases, reducing pressure by extracting molecules from a confined space. This enables systems to lift, hold, convey or shape materials.

Creating a vacuum involves controlling the flow and compression of gas to maintain consistent performance. Different pump technologies achieve this in various ways — through mechanical compression, momentum transfer, or fluid dynamics. These techniques aim to reduce the pressure within a controlled volume to the level required by a specific application.

How Does a Vacuum Pump Work?

A vacuum pump works through three interrelated principles and their interaction across different stages of vacuum:

- Pressure is the measure of force exerted by gas and air molecules against the walls of a container. A pump lowers the pressure by removing a molecule, which creates the vacuum effect.

- Flow rate, often referred to as pumping speed, indicates the volume of gas a pump can remove over a given period. Maintaining sufficient flow prevents the vacuum level from fluctuating, which can affect product quality or process efficiency.

- Ultimate vacuum is the lowest pressure a pump can achieve under ideal conditions. It represents the performance limit of the pump and supports processes that require extremely low pressure, such as freeze-drying or laboratory applications.

Types of Vacuum Pumps

Vacuum pumps come in several distinct types, each suited to different industrial requirements and operational conditions.

1. Rotary Vane Vacuum Pumps

Rotary vane pumps operate using a rotor mounted off-center within a cylindrical housing. Vanes slide in and out of slots in the rotor as it rotates, trapping gas between the vanes and the housing. As the rotor spins, these trapped volumes are compressed and expelled, which reduces the pressure in the system. Oil-lubricated versions are common, as the oil provides sealing and cooling.

Rotary vane pumps are commonly used in packaging and laboratory operations due to their robustness and predictable performance. They maintain smooth pumping cycles and consistent vacuum levels.

2. Rotary Screw Vacuum Pumps

Rotary screw vacuum pumps use two intermeshing helical screws that rotate in opposite directions. Gas is trapped in the cavities formed between the screws and the housing, and then compressed centrally along the screws toward the discharge.

Rotary screw pumps are often selected for chemical processing, large-scale packaging or automation lines. They can maintain steady pressure under variable conditions.

3. Dry Running Rotary Claw Vacuum Pumps

Claw pumps feature claw-shaped rotors that rotate in opposite directions. Gas is trapped between the rotors and the casing and conveyed toward the exhaust. Because they operate without oil, these pumps prevent contamination while offering high reliability under challenging process conditions.

Claw pumps excel in the pharmaceutical and food processing industries. Their durability and dry operation make them attractive for processes with vapor-laden gases.

4. Liquid Ring Vacuum Pumps

Liquid ring vacuum pumps use a rotor spinning in a cylindrical housing filled with a sealing liquid. The liquid forms a ring under centrifugal force, trapping and compressing gas as the rotor rotates. Gas is expelled at the discharge, while the liquid ring continuously seals the pump.

Liquid ring pumps are commonly used in chemical processing, food production and wastewater treatment. They can manage varying gas compositions while maintaining a stable vacuum, which makes them versatile for demanding industrial settings.

5. Articulated Piston Vacuum Pumps

Articulated piston pumps use a piston to compress gas in a cylinder. The piston moves in a precise orbit or linear motion, drawing in air or gas during the intake stroke and compressing it during the exhaust stroke. This robust design allows high-volume gas handling at rough to medium vacuum levels.

Articulated piston pumps are often deployed in heavy-duty industrial processes, including plastic extrusion and chemical distillation. They offer flexibility in stand-alone and integrated vacuum systems.

Benefits of Vacuum Pumps

Vacuum systems influence efficiency and product quality across industrial applications. When selected and maintained correctly, they can support stable processes and sustainable performance. Explore the benefits of vacuum pumps below.

Improves Plant Processes and Efficiency

Vacuum pumps boost operational precision by maintaining consistent vacuum levels. They enable operators to reliably hold, form, convey or package materials. In automated systems, this precision reduces errors, scrap and rework. Efficient evacuation accelerates drying, sealing or shaping, which shortens cycle time and increases throughput.

Vacuum systems also provide flexibility in production. For example, in thermoforming plastics, a stable vacuum ensures even material draw and fewer defects, while in automated assembly, vacuum-assisted pick and place systems secure components accurately and consistently.

Supports Energy Savings

Vacuum pumps contribute to energy optimization. For example, rotary screw pumps with variable speed drives match output process to demand, which prevents unnecessary over pumping. Manufacturers may notice a reduction in energy consumption by operating at only the necessary speed. Efficient pumps also demand less input power to achieve the same vacuum levels, which may lead to electricity savings over their operational lifespan.

Additionally, pumps that operate within their optimal performance envelope produce less waste heat, which reduces the need for additional cooling systems.

Enhances Worker Safety and Environmental Compliance

Vacuum pumps enhance workplace safety by controlling gases and particulates within enclosed systems. By minimizing exposure, employees operate in a safer environment, and processes remain cleaner and more contained. Dry vacuum pumps eliminate the risk of oil contamination, while liquid ring designs can safely manage corrosive or humid gases.

Noise reduction also improves workplace comfort, helping maintain safe and productive conditions. In terms of environmental compliance, vacuum pumps contribute to sustainability by reducing the release of volatile compounds and other process emissions.

Improves Equipment Reliability and Product Quality

Vacuum pumps help maintain production equipment reliability and product outcome consistency. These systems reduce unplanned downtime through proactive maintenance, with components inspected regularly to prevent failure. Robust designs, including rotary screw and claw pumps, minimize wear on moving parts, extending service life and reducing replacement costs.

Consistent vacuum levels ensure uniform process conditions. For example, in packaging operations, stable vacuum prevents seal defects, while in chemical processing, it ensures uniform concentrations.

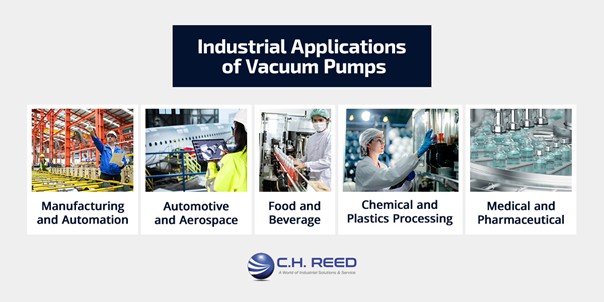

Industrial Applications of Vacuum Pumps

Vacuum pumps are integral across a wide range of industries. They support processes that require precise pressure control, efficient material handling and consistent product quality. Explore vacuum pump uses below.

Manufacturing and Automation

In manufacturing and automation, vacuum pumps are ideal for systems that require precise handling and consistent material movement. Manufacturers can use them in pick and place applications, where robotic arms or automated conveyors lift and position components.

Vacuum pumps also support forming and shaping processes, such as thermoforming plastics or glass molding, by creating the pressure differential needed to accurately hold or shape a material.

Conveying systems for powders or small parts rely on a vacuum to move products while minimizing contamination or loss. This helps provide a controlled and efficient method for material transport across production lines.

Food and Beverage

Vacuum technology helps maintain product quality, shelf life and safety in the food and beverage sector. Operators use them in packaging systems to remove air so seals remain tight. In freeze-drying, vacuum pumps remove water vapor from products, allowing for moisture removal at lower temperatures and preserving the flavor and nutritional content.

Modified atmosphere packaging also relies on vacuum to remove oxygen and introduce inert gases, which helps reduce oxidation and extend a product’s freshness. Apart from packaging, vacuum systems support drying and material handling operations in food production. Manufacturers can maintain process efficiency while meeting hygiene and quality standards.

Medical and Pharmaceutical

In medical and pharmaceutical applications, vacuum pumps provide the controlled environments necessary for production and laboratory operations. They are used for sterilization and drying, helping autoclaves and freeze drying systems remove moisture from sensitive equipment or products. Laboratory processes such as filtration, distillation, and vacuum-assisted chemical reactions require stable vacuum levels for precision and reliability.

In medical facilities, a vacuum is used in surgical or dental suction systems to efficiently remove fluids. Across the sector, these pumps ensure product integrity and operational safety.

Automotive and Aerospace

Vacuum technology supports automotive and aerospace manufacturing. These systems support vacuum forming for composite components, allowing manufacturers to mold complex shapes. They are also used in leak detection systems to ensure fuel or hydraulic assemblies meet exacting standards.

Additionally, vacuum pumps are applied in testing and evacuation processes during assembly to maintain quality and performance specifications. Manufacturers can achieve high precision and throughput by providing controlled pressure environments.

Chemical and Plastics Processing

In chemical and plastics processing, degassing operations use vacuum pumps to remove dissolved gases from resins and chemical solutions. Vacuum distillation lowers the boiling point of substances, which allows separations to occur at lower temperatures. Additionally, vacuum-assisted drying reduces the temperature required to remove moisture or solvents, helping preserve the integrity of sensitive materials.

Vacuum pumps maintain controlled pressure for shaping, forming and conveying materials in plastic extrusion or molding processes.

How to Select and Use a Vacuum Pump

Selecting the right vacuum pump requires a careful assessment of your operational needs and goals. Here are some factors to guide your decision:

- Application requirements: Determine the required vacuum level and performance for your specific process. Consider the type of gases or vapors involved, the expected duty cycle, and whether your process requires rough, medium, high or ultra-high vacuum. Matching pump capability to the application ensures consistent results.

- Operating conditions: Assess temperature, humidity and the presence of particulates or corrosive substances. Some designs, such as claw or liquid ring pumps, can tolerate harsh or vapor-laden conditions, which helps maintain reliability and performance.

- Budget and total cost of ownership: Consider up-front costs and long-term operational expenses. Efficient pumps that reduce energy consumption and increase maintenance intervals deliver savings throughout the equipment’s lifetime.

- Maintenance and service requirements: Vacuum pumps that are easier to maintain or service allow your maintenance team to maximize uptime. Following recommended service intervals and using the right lubricants or fluids supports consistent vacuum pump performance and product quality.

The Importance of Vacuum Pump Maintenance

Vacuum pump performance depends on consistent maintenance. These systems operate under demanding conditions, so routine maintenance is essential to protecting your equipment and maintaining stable processes.

Maintenance Procedures for Vacuum Pumps

When you schedule pump maintenance around predictable intervals and targeted checks, you protect performance and maintain consistent vacuum levels across your processes. Some components of a reliable maintenance program include:

- Regular inspections: Routine inspections create opportunities to catch early signs of wear, performance drift or component malfunction. During these checks, assess vacuum levels, examine seals and fittings, and listen for changes in noise or vibration.

- Pump oil management: For lubricated pumps, clean oil reduces friction, supports internal sealing and regulates temperature. Oil absorbs contaminants and residues, depending on the application. Monitoring clarity and replacing the oil at recommended intervals helps protect internal surfaces and sustain the pump’s ability to reach its intended vacuum level.

- Leak inspection: Regular leak checks help confirm the integrity of the vacuum system and maintain pressure stability. Addressing leaks early reduces operational strain on the pump and ensures your system consistently reaches its target vacuum.

- Filter maintenance: Filters help protect the vacuum pump from particulates and debris that can enter the system during normal operation. Cleaning or replacing filters on schedule ensures uninterrupted airflow and supports consistent vacuum performance. Proper filter maintenance also improves service life by preventing the buildup of contaminants.

Best Practices to Support Reliability

Consider maintenance routines to keep your vacuum system stable and predictable. Best practices include:

- Keep a detailed maintenance log: A structured log helps track service intervals, performance trends and oil changes, and component replacements. Review this data to make informed decisions about maintenance timing and track changes in pump behavior that may require attention.

- Maintain clean and well-ventilated settings: Vacuum pumps perform best when heat and airborne contaminants are controlled. A clean, well-ventilated space helps prevent dust from entering filters or seals and supports proper cooling. Keeping vacuum pumps away from heat sources or areas with restricted airflow can extend pump life and improve energy efficiency.

If you notice a persistent decline in vacuum performance or system instability after routine maintenance, a professional assessment can help identify the underlying cause. Complex repairs, internal component replacements, precision alignments and advanced diagnostics are often best handled by experienced service providers.

Partner With C.H. Reed for Your Vacuum Pump Needs

C.H. Reed understands that vacuum pumps keep your operations running efficiently. With decades of experience, we provide quality vacuum pump solutions that improve plant processes, enhance energy efficiency and strengthen worker safety. Our expertise spans a wide range of industries. We’ll work with you to understand your processes, assess your needs and recommend pumps that augment equipment reliability and operational efficiency.

We know that you need your pumps to remain in good condition. For this reason, we provide vacuum pump maintenance services so you can keep your systems operating with minimal downtime.

Contact us today to schedule a consultation and let our experts guide you to the pump that meets your specific needs.

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…