April 11, 2024

The Importance of Vacuum Pump Filtration

SHARE THIS POST

The Importance of Vacuum Pump Filtration

What are Vacuum Pumps and What are they Used for?

Vacuum pumps are mechanical pieces of equipment that remove gasses and molecules from a confined space, creating a “vacuum effect” used to complete a variety of different tasks. Vacuum pumps are often used by manufacturing, industrial, and medical industries for applications like forming, shaping, holding, lifting, moving, clean environments, preserving, cooling, drying, and more.

Why do Vacuum Pumps Need Filters?

Vacuum pumps are volumetric (positive displacement) machines that move gas from one region to the next to create a vacuum by changing high and low-pressure states. In theory, they take gas molecules at their inlet and push it to the outlet.

What this means is, whatever the end-user of the vacuum pump is doing will ultimately get pushed through the pump. Manufacturing and industrial processes can create an excess number of different contaminants. If not properly filtered at the inlet, those contaminants will make their way into the equipment causing breakdowns, equipment failure, pressure drops, and an array of other costly problems.

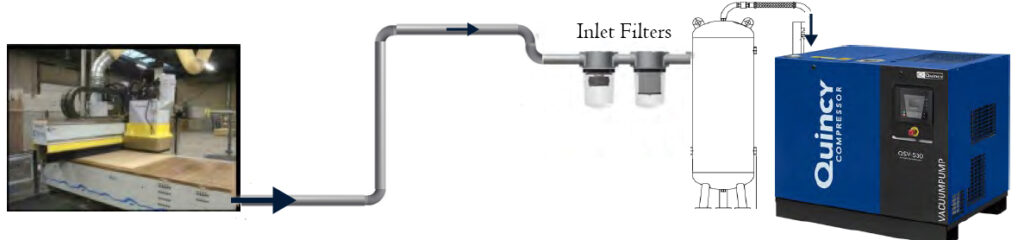

For example, say a customer is using a vacuum pump to power their CNC routing machine. As the vacuum pump creates the necessary hold-down force to keep the piece of wood in place on the router, it is also pulling the dust and harmful particulates created in that application towards the vacuum pump. Vacuum pump inlet filters remove those harmful particulates before they reach the pump, prolonging the life of your equipment and making it more efficient.

Different Contaminants Harmful to Vacuum Pumps

Contaminants created during manufacturing processes can be very damaging to vacuum pump systems, if not properly filtered out before the inlet. The idea is to capture and remove these contaminants prior to reaching your pump to avoid pressure drops, inefficiencies, and breakdowns. The three main contaminants that are harmful and need filtered out are particulates, liquids & mists, and vapors.

- Particulates: Often measured in micrometers, particulates are tiny particles of solid or liquid matter suspended in the air. Examples are dust particles, dirt, soot, smoke, and microscopic liquid droplets.

- Liquids and Mists: Some manufacturing operations create various liquids and mists that remain present in the facility’s air supply, and should be removed prior to a vacuum pump’s inlet. Examples include several metal product manufacturing operations where they have to mist oil into the metal product production process (i.e. metal stamping). The oil misted into the process lingers in the air in the facility.

- Aerosols and Vapors: In more extreme manufacturing applications, certain processes can emit dangerous aerosols and vapors that can fail a pump. In some cases, a combustion event can take place, depending on the chemical compounds involved. Filtration systems are put in place to remove these harmful byproducts to keep equipment in efficient operation.

Different Types of Vacuum Pump Filters

There are several different kinds of inlet filters that vacuum pumps use to prevent contaminants from reaching the pump. From simple screen-type filters to more elaborate bag houses, and medical-grade filtration systems, the configuration you choose should match the requirements of the vacuum pump to the application or process.

- Particulate Filters: To filter out particulates before they enter the inlet of the vacuum pump, high-efficiency media filters are used. These filters are engineered to remove particles smaller than 1 micron, and are available in various types (HEPA, ULPA, PTFE) depending on removal rates and applications. They also come in different media options and endcap styles.

- Filters for Liquids and Mists: Liquid and multistage separators and inlet vacuum filters can be used to pull those harmful liquids out of the air supply before reaching vacuum pump inlets. With this style of filter, larger particles and liquid are separated, drop down, and are collected at the bottom of the separator. A float capsule within the separator screen rises with the liquid level until max capacity and limits the flow, protecting the pump from getting damaged.

- Filters for Aerosols and Vapors: A vapor condensing trap can be used to ensure these dangerous and destructive vapors are effectively removed prior to reaching the equipment.

- Vacuum Pump Discharge Filters: Another important filter for vacuum pumps is on the discharge side of the unit. Oil-sealed vacuum pumps discharge oil and “smoke” during their operation. Unfiltered discharge can create oily residue on surfaces near the outlet. This can also spread unpleasant odors throughout a workplace. Lastly, failing to capture these emissions can waste valuable pump oil and induce workplace safety issues. The solution is oil mist filters and air/oil separators for the discharge side.

High efficiency media filters for particulates

Liquid and Mist Separators

Vapor Condensers for Vacuum Pumps

Oil mist filters for the discharge side

Other Vacuum Pump Filtration Accessories Include:

- Filter Silencers: Also called air mufflers, filter silencers help filter the air stream as well as provides an effective noise attenuation by reducing dB levels and softening the pitch generated by the vacuum pump.

- Prefilters: Foam prefilters add an extra layer of coarse filtration that help extend the life of your primary filter element, helps lower maintenance costs, and increases dust holding by up to 50%.

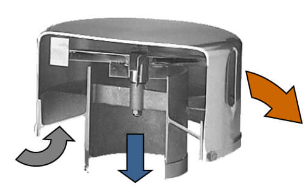

Solberg SpinMeister Precleaner

- Precleaners: Solberg’s SpinMeister Precleaners are used to clean the air prior to the intake filter. How it works is air gets drawn through louver plates which direct the air to turn the rotor. Centrifugal force separates the contaminants from the airstream, pushing them to the outer perimeter of the cover, expelling them through the discharge port. Cleaner air is drawn to the lower chamber and filtered by a 99% efficient pleated element.

- Gauges: Gauges help monitor filter performance, pressure drops, and provides you with a general idea of when it’s time to change filters.

- O-Rings, Gaskets, Fasteners: We can also help you source the necessary O-rings, gaskets, fasteners, and brackets needed to properly maintain your vacuum pumps.

Benefits of Proper Vacuum Pump Filtration

With all that said, what is the importance of vacuum pump filtration? The projected service life of a vacuum pump system comes down to how well it is protected from incoming contamination. A properly filtered vacuum system will simply have a longer service life, reduce pressure drops, reduce unexpected downtime, reduce costly emergency repairs, and increase the plant’s energy efficiency. Combined, all these benefits lead to an overall lower cost of ownership for the business.

Partner with C.H. Reed for Vacuum Pump Solutions

Contact C.H. Reed for your next vacuum pump project. Whether that be design and installation of a new system, filters and aftermarket parts, or vacuum pump service and preventative maintenance. Our team of factory-trained vacuum specialists are ready to help you meet your vacuum goals!

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…