July 23, 2025

How Industrial Equipment Is Transforming the Wine Industry

SHARE THIS POST

How Industrial Equipment is Transforming the Wine Industry

An era in winemaking has already arrived, driven with confidence, environmental-friendly, and efficiency. From vineyards to large-scale producers, winemakers have already came up with production strategies, and utilizing industrial equipment to keep up the demand for qualities of wine. Industrial equipment is reshaping the wine industry today for making ends meet.

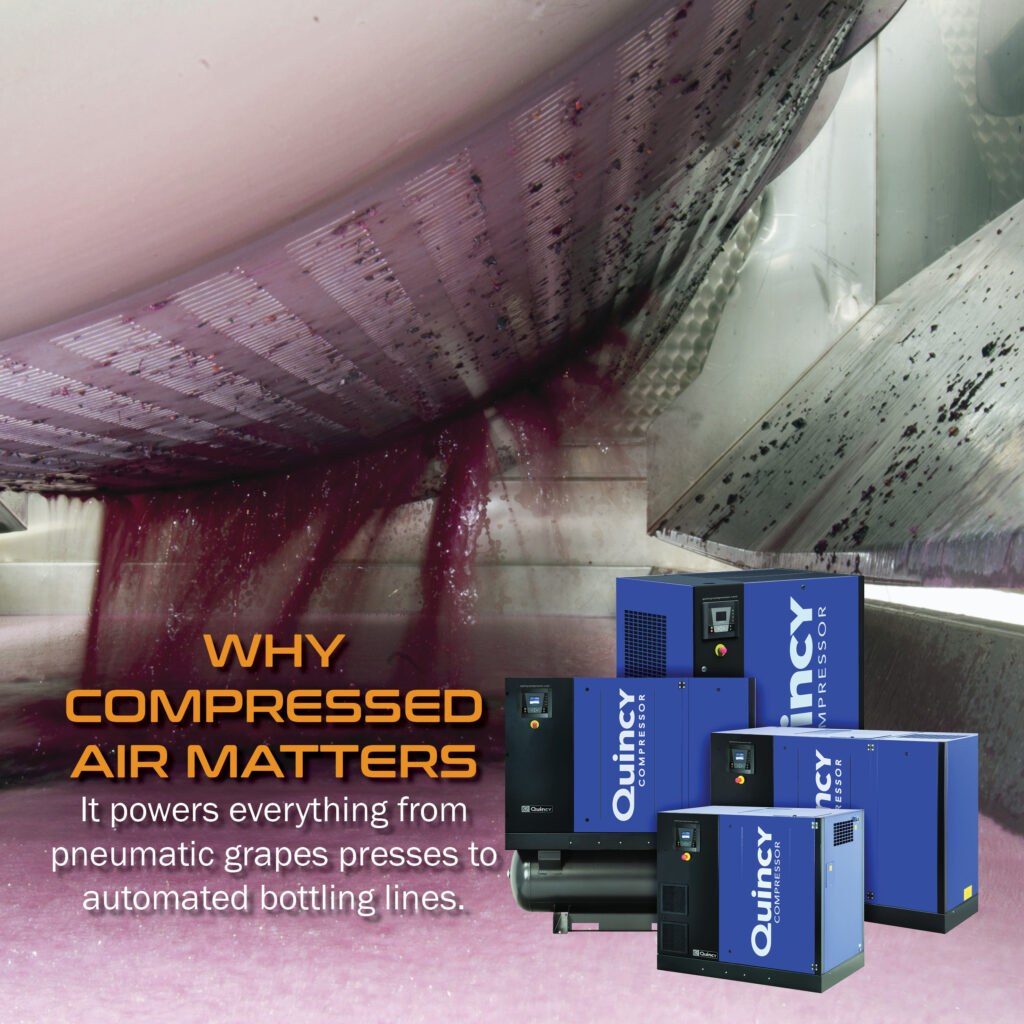

Compressed Air Matters in Winemaking

Compressed air is important in contemporary winemaking. The air powers pneumatic grapes presses, bottling lines, cleaning the systems, and most of all improving the efficiency and precision. Since compressed air system is important for everyone, wineries can streamline production, minimize interruption, and lower labor costs.

Nano C1 : Smart Cooling for Contemporary Winery

Nano C1 Industrial Chillers are engineered to deliver precision performance in demanding like wineries, breweries, and food manufacturing. They provide reliable and consistent temperature control across various of applications. This is included in fermentation cooling, tank chilling, storage temperature maintenance, and more.

Here are some key features of Nano C1 Chillers:

- Wide Cooling Capacity Range: Available in multiple of sizes to suit small-batch wineries or high-volume producers. Whether you’re running a single fermentation tank or multiple of vessels, there’s a Nano chiller that fits your operation.

Energy Efficient Operations: Nano C1 Chillers use scroll compressors and high-efficient heat exchangers to minimize power consumption without sacrificing cooling power.

Energy Efficient Operations: Nano C1 Chillers use scroll compressors and high-efficient heat exchangers to minimize power consumption without sacrificing cooling power.- Simple Integrating: The chillers are ready and can be installed without a hassle with less downtime. The equipment can incorporate with existing tank systems, process controls and piping configuration.

- Built-in Water Reservoir with Pump: Planned for suitability, the units are included with an integrated water tank and pump, and eliminating the steps for searching for separate components and minimizing requirements.

- All-Weather Durability: Built for indoor and outdoor installation. They are housed in all-weather resistant cabinets and designed to perform reliably even in extreme temperature conditions.

Whether you are fermenting reds or storing fine whites, the Nano C1 Chiller can help you achieve the right temperature which targets critical to preserving the wine quality and flavor.

Fermentation Control Made Easy

Fermentation is an exothermic process, meaning it produces heat. If not taken cared of, fermentation temperatures can rise above 85-105 degrees, potentially pausing fermentation and having a lesser quality of wine. With a Nano C1 Chiller, winemakers gain peace of mind knowing that the process is controlled and stable, leading to predictable results and better wine. Including, temperature reduces the need for chemical preservatives like sulfur dioxide, helping you create a cleaner for a more natural wine.

Take Control of Your Malolactic Fermentation

Malolactic fermentation (MLF) is a critical process in red blends and some white wines. MLF can reduces harsh malic acid, lighten the flavor, and adds some complexity. If not managed correctly, uncontrolled MLF after bottling can ruin a batch of wine. Our Nano C1 Chillers can help to maintain the prime temperature around 77 degrees for MLF to move forward safely, keep away from spoilage and off flavors.

Why Nitrogen Matters in Winemaking: Quality, Protection and Profitability

When it comes to producing world-class wine, few elements are as vital and as underrated as nitrogen. From grape pressing to bottling, nitrogen plays a behind-the-scenes role in protecting wine quality, extending shelf life, and reducing waste. Alongside with nitrogen, compressed air is also essential in powering key equipment and process throughout the winery.

Modern wineries are now turning to on-site nitrogen generation systems as sustainable, cost-effective alternative to traditional cylinder delivery. Here’s why nitrogen is becoming a must-have in today’s winemaking toolkit.

The Role of Nitrogen in the Wine Industry

Nitrogen is a static, non-reactive gas which doesn’t interact with wine elements. It can act as a barrier, blocking the airflow of oxygen from entering the winemaking process. Oxygen can lead to oxidation spoilage and turn off flavors.

Here are some ways nitrogen is used in wineries:

- Tank and Barrel Blanketing – During fermentation, aging, and storage, nitrogen blanketing is used to displace oxygen from the headspace in barrels and tanks. This minimizes the risk of oxidation and microbial contamination. Helping to preserve the wine’s integrity over time.

- Purging and Sparging – Nitrogen is used to purge pipelines, tanks, hoses and bottles before wine contact. This removes residual oxygen that could damage the wine or introduce inconsistencies in carbonation and taste.

- Bottling and Packaging – Before corking or capping, nitrogen fills the headspace in each bottle, creating a protective environment that prevents oxidation during storage and transit. This step is essential for maintaining freshness and flavor from the winery to the consumer’s glass.

Benefits of Using Pneumatech Nitrogen in Winemaking

Using nitrogen throughout your winemaking process delivers measurable benefits:

- Oxidation Prevention: Protects wine’s flavor, aroma, and color by minimizing oxygen exposure.

- Shelf-Life Extension: Preserves quality over time, especially for export and long-term storage.

- Consistent Carbonation: Supports stable sparkling wine production by removing dissolved oxygen.

- Reduces Sulfite Use: Lower oxygen levels reduce the need for sulfur dioxide preservatives.

- Cleaner, Safer Bottling: Ensure hygienic packaging environments and prevent spoilage.

Pneumatech On-Site Nitrogen Generators: A Smart Winery Investment

To meet the rising demand for quality and efficiency, many wineries are moving away from bottled gas and adopting Pneumatech’s food-grade nitrogen generators. These systems are designed with the wine industry’s specific needs in mind like delivering purity, reliability, and cost control.

Pneumatech Solutions:

PSA (Pressure Swing Adsorption) Models – PPNG HE Series

- Nitrogen purity levels from 99.5% – 99.999%, ideal for wine protection.

- Fully compliant with global food-grade standards.

- High-performance systems with energy-saving algorithms that reduce power consumption by up to 40%.

Membrane Technology:

Membrane technology is a very simple, reliable and continuous N2 production method. Compressed air is pushed through hollow polymer membranes. The oxygen in the air escapes through the fiber walls and permeates into the atmosphere. This leaves quality nitrogen with a purity between 95% and 99.5% at the generator outlet.

Final Sip: Elevate Your Wine, Lower Your Costs

Whether you’re a boutique winery or a large-scale producer, investing in on-site nitrogen generator is a gamer changer. Not only do you protect your wine from spoilage and oxidation, but you also improve operational efficiency, reduce costs, and support sustainability.

Add compressed air to the mix. Powering everything from pneumatic process to bottling lines and you gain even greater control over production. Combine that with precision temperature management using industrial chillers, and your winery is fully equipped for quality, consistency and scalable growth.

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…