April 7, 2020

New Products from Col-Met Engineered Finishing Solutions

SHARE THIS POST

Col-met is a leader in paint booths, powder booths, ovens, washers, air makeup units, and other finishing systems for industrial, automotive, truck and large equipment, and woodworking markets. They recently launched 6 new products to the market that are worth highlighting:

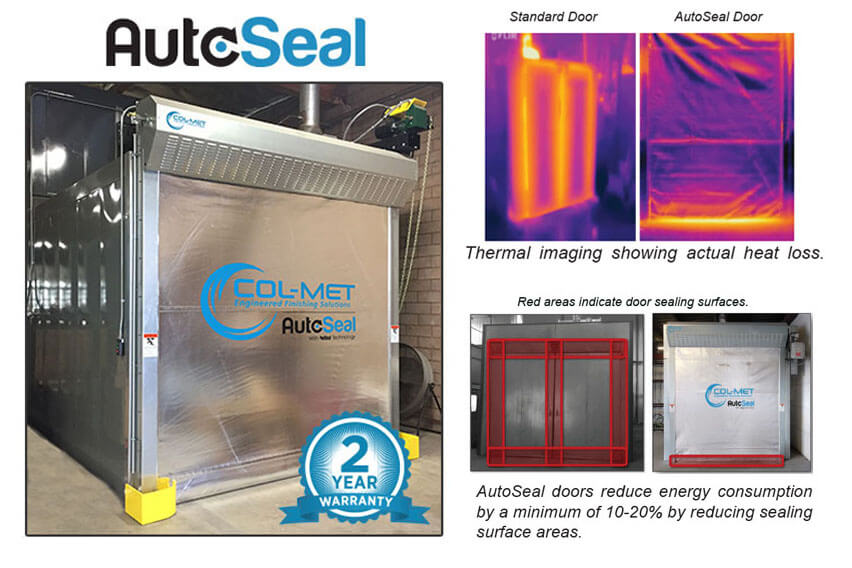

AutoSeal – Batch Oven Roll Up Door: Industrial ovens need to have a door system with reliable, durable seals; especially if the doors are continuously being opened and closed. Col-Met’s AutoSeal Roll Up Door is designed with patented air-tight sealing technology that delivers extreme energy efficiencies, improved worker safety, requires less maintenance than traditional doors, and has a smaller footprint, saving you floor space.

- 10-20% energy savings compared to traditional oven doors

- Reduces energy lost each time the door is opened

- Increased workflow

- Minimizes footprint requirement

- Quick, easy install

- Easy access remote control or push button wall station

- One year ROI based on energy savings

- Impact-resistant

- Improved safety as operators are not exposed to hot air while opening

- Flame resistant aluminized fabric with cool to the touch exterior

- 2-Year warranty

E-Light LED Booth Lighting: Proper booth lighting is essential in achieving high-quality finishes. The new E-Light LED Lighting outperforms fluorescent booth lighting through increased energy efficiencies, much longer life, delivering true-color renderings, increased durability, reduced maintenance, and improved safety.

- On average, half the energy usage than standard fluorescent

- Last 5 to 10 times longer

- Easy-to-install retrofit kits available

- More vibrant color with true-color rendering

- Does not deteriorate over time

- 4000 and 8000-lumen models available

- Dimmable models available offering more energy savings when full illumination is not needed

- 22 gauge steel construction with white powder coat = high reflective finish

- 5-year warranty

FilterLoc – Zip-to-Lock Filter Technology: FilterLoc provides a tighter filter seal to the paint booth, eliminating overspray bypass into the exhaust chamber. This provides savings by allowing the utilization of roll media reducing overall filter costs. FilterLoc is for use with all Col-Met W-Series Products. It is designed to be mounted to the spray booth and offers quick and easy filter changes without clips or pins. Once the track is mounted, it takes only seconds to lock the filter in place.

FilterLoc – Zip-to-Lock Filter Technology: FilterLoc provides a tighter filter seal to the paint booth, eliminating overspray bypass into the exhaust chamber. This provides savings by allowing the utilization of roll media reducing overall filter costs. FilterLoc is for use with all Col-Met W-Series Products. It is designed to be mounted to the spray booth and offers quick and easy filter changes without clips or pins. Once the track is mounted, it takes only seconds to lock the filter in place.

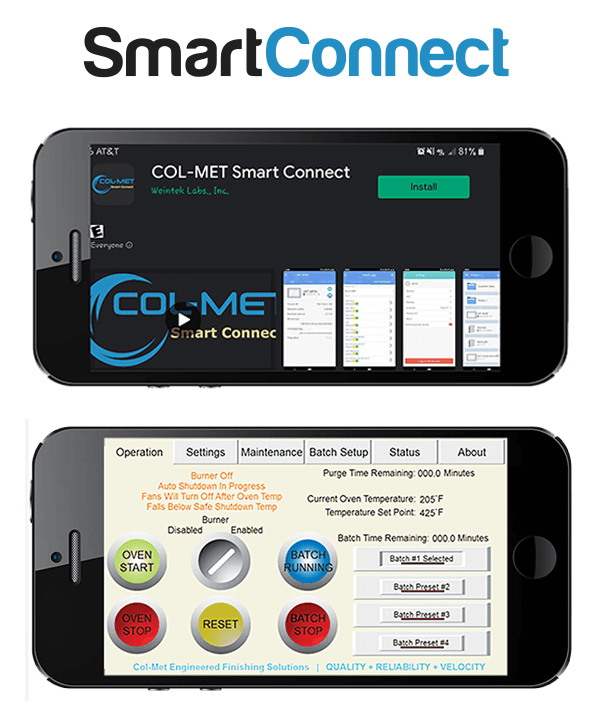

SmartConnect Oven App: The new SmartConnect Oven App allows users the ability to remotely view oven status when the control panel is connected to the internet. You can monitor temperature, process times, elapsed time, system faults, or burner status remotely. You can receive text notifications for batch complete, oven temps out of range, system faults, or preventative maintenance schedules with a yearly subscription (free for the first year). This app is simple and user-friendly with screens that mirror the oven’s touch screen panel. The app can be accessed using any Android, PC, or Apple device.

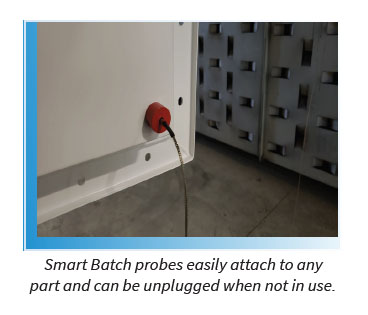

SmartBatch Oven Accessory: This patent-pending technology allows for real-time monitoring of part temperature by incorporating temperature probes into the design of the batch oven and control panel that monitor part temp. during the curing process. The info gathered can be used to control cure times, as well as document your processes. When used with the SmartConnect App mentioned above, you can remotely monitor part and oven temperature, batch time, system faults or out of range occurrences with any Android, PC, or Apple device.

TangentProcess – A Completely Different Approach to the Spray Application Process: This patent-pending process moves away from traditional rectangular shaped spray booths and linear part travel; offering a completely different approach to the spray application process. Col-Met’s TangentProcess accommodates a non-linear conveyor path that increases the available application time. This allows the product being coated to be in the process area up to three times longer. In addition, the process also maintains optimal applicator-to-target distance, equaling increased transfer efficiencies and improved finish quality. Once the optimal part path has been established, the TangentProcess spray enclosure is custom designed to complement the desired process and maximize capture efficiency. These optimizations can include multiple exhaust chambers which eliminates downtime for required filter change-outs.This process can be used for manual, robotic, liquid or powder coating applications. (When used for robotic powder applications, the booth’s design allows the robot to perform booth blow-down operations for cleaning and color changes. If two robots are installed, the robots may even be used to clean each other.)

- Patent-pending technology where parts travel around a manual spray operator or automated robot

- Offers 3 times longer spray time than linear conveyor systems

- Easy filter changes without stopping production reduces downtime

- Capturing of overspray is maximized by unique booth design

- Booth design is based on coating process requirements and can be easily adapted to customer needs

- Easily spray all sides of a part

- Robot friendly designs

- Compact and space-saving

To learn more about any of these engineered finishing solutions from Col-Met and what they can add to your finishing process, simply contact C.H. Reed to speak with one of our Paint Finishing Specialists.

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…