June 1, 2020

Pump Applications for Wastewater Treatment in Manufacturing

SHARE THIS POST

Pump Applications for Wastewater Treatment in Manufacturing

Water is an instrumental resource used in every manufacturing facility around the world. However, almost all manufacturing plants generate some form of waste stream. These waste streams need to be treated before being discharged back into the environment or municipal water system. To be treated, the wastewater treatment plant removes the dissolved solids from the waste stream and concentrates it, which enables the clean water to be recycled or discharged. The other option is to have the waste hauled away for processing at an off-site facility, which oftentimes is very expensive. Regardless if facilities treat their waste streams on-site or have it hauled it away, wastewater treatment is growing globally due to the increasing enforcement of environmental regulations that require more stringent control to lower emissions.

Wastewater Treatment Processes & Pump Applications

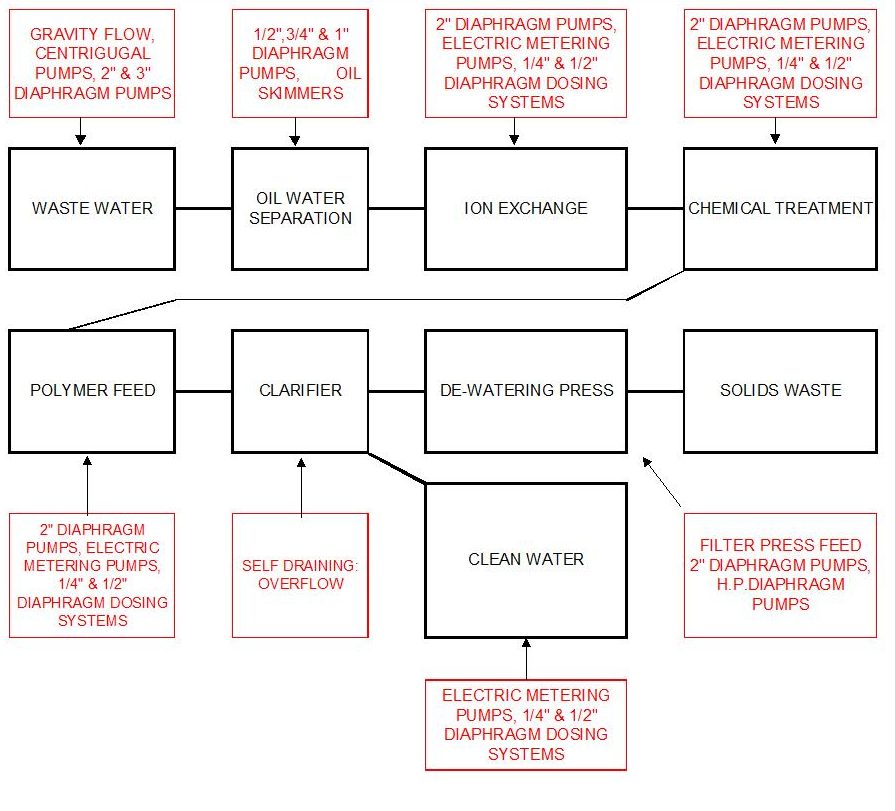

Most medium to large-sized manufacturing facilities have on-site wastewater treatment areas where diaphragm pump and hose pump technology is used. Typical wastewater treatment processes where these pumps are used include:

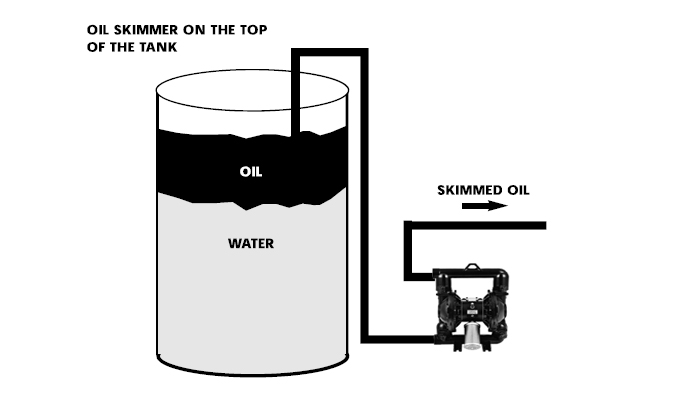

- Oil-Water Separation: If the plant’s waste stream contains oil, the oil must be separated from the water prior to discharge. Since oil is lighter than water, it floats to the surface. An oil-water separator is used to simply skim the oil off the surface by means of a polypropylene belt then is squeezed into a holding tank.Air operated diaphragm pumps (AODs) are used to supply the wastewater to the oil-water separator and to pump the oil from the holding tank. AODs are popular in this application because of their gentle pumping action, unlike high RPM centrifugal pumps that can emulsify the oil and make it difficult to remove. AOD’s are also popular here because they can run dry without damaging the pump.

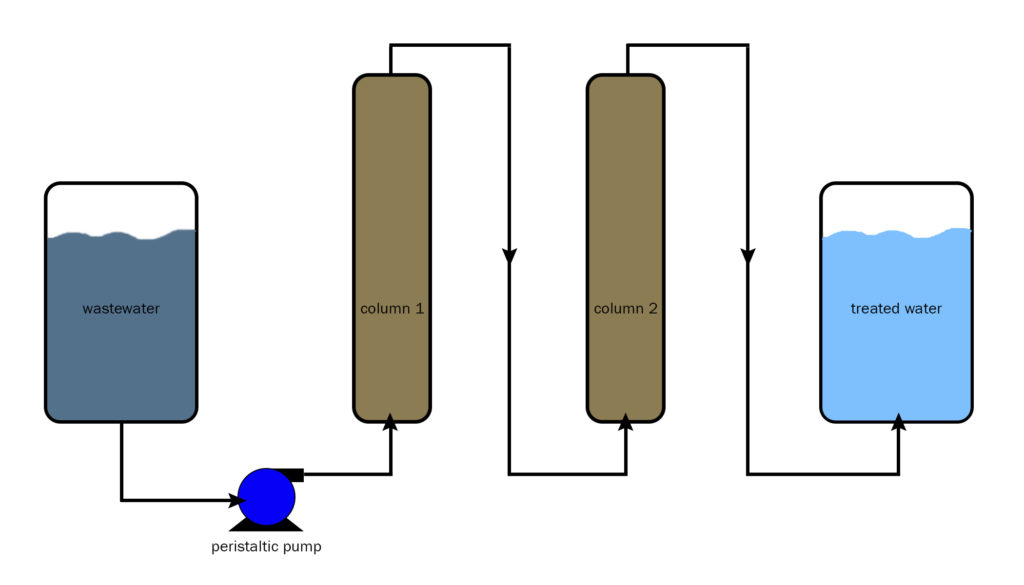

- Ion Exchange: Different equipment is used in wastewater treatment depending on what contaminants must be removed. Metal ion exchange, for example, is utilized when metal ions like cadmium, copper, nickel, or chromium need to be removed. Typically, ion exchange systems consist of two ion exchange columns. Column #1 contains strong acid cation resins. Column #2 contains base resin. Wastewater enters column #1 to be de-cationized; the resulting acid solution is then transferred to the second column where anions are replaced by hydroxyl ions; dissolving metal contaminants and making the wastewater free of toxic metals.In ion exchange, peristaltic pumps are used to feed the wastewater into the columns and to inject acid and caustic resin solutions after the regeneration process.

- Chemical Treatment:

Some waste streams contain cyanide, which can be changed into a harmless chemical by chemically treating it. This process raises the pH level to 11 by adding suitable Alkali (typically Sodium Hydroxide) followed by an addition of chlorine (typically Sodium Hypochlorite.) This process turns cyanide into cyanate. From there, the cyanate is treated even more, turning it into harmless carbon dioxide.Pumps are used in chemical treatment to dose and meter the various chemicals in the waste stream. For example, Graco’s Husky ¼” pump with remote ports can be connected to a control box that powers the pump using an external solenoid valve, which controls the pump’s dosing rate. Pumps are also used for adjusting the pH in the tanks. Maintaining a consistent pH is essential to produce the right amount of flocculation once the polymers are added in the next step. The pH is monitored by sensors, which will turn on the appropriate pump to either lower or raise the pH.

Some waste streams contain cyanide, which can be changed into a harmless chemical by chemically treating it. This process raises the pH level to 11 by adding suitable Alkali (typically Sodium Hydroxide) followed by an addition of chlorine (typically Sodium Hypochlorite.) This process turns cyanide into cyanate. From there, the cyanate is treated even more, turning it into harmless carbon dioxide.Pumps are used in chemical treatment to dose and meter the various chemicals in the waste stream. For example, Graco’s Husky ¼” pump with remote ports can be connected to a control box that powers the pump using an external solenoid valve, which controls the pump’s dosing rate. Pumps are also used for adjusting the pH in the tanks. Maintaining a consistent pH is essential to produce the right amount of flocculation once the polymers are added in the next step. The pH is monitored by sensors, which will turn on the appropriate pump to either lower or raise the pH. - Polymer Transfer: Once all the oils, cyanide, and various metals are removed from the plant’s waste stream, there will be leftover particulate floating in the solution. Polymers are used to concentrate the solids and are injected into the waste streams (using pumps) before entering the clarifier to de-water the remaining sludge and separate it from the clean water.The pumping system for the polymer feed is generally the same as the chemical feed. Dependent on the tank size, the flow of wastewater stream, and the subsequent amount of polymer required, the size of the pumps will vary. Quarter and half-inch pumps are often used.

- Clarifier Process: Pumps are sometimes used to transfer the waste streams to a clarifier, a hopper-style tank with a lamella plate pack. (However, some clarifier tanks sit lower than the holding tank, eliminating the need for a pump. This allows for a natural flow of treated wastewater flowing to the clarifier.) The lamella plate pack consists of corrugated parallel plates, which give the clarifying capacity of conventional settling tanks 10x its size. These systems produce 2-6% sludge solids, which settle out in the bottom of the hopper where they are pumped to a filter press or another type of dewatering device.

- De-watering Process: The most common and least costly way to de-water the sludge from the clarifier is with a filter press. A filter press is made up of numerous plates fitted with a filter cloth between each of them. These plates are then pressed firmly together. Using a pump, the slurry is injected into the plates. Once full of sludge, the filter press then puts hydraulic force on the plates to squeeze out any remaining water. The plates are then separated, dropping a dry, cake-like substance into a collection bin so it can be disposed of.

Below is an overview of the wastewater treatment process highlighting the many areas where pumps are used:

Ultimately, diaphragm pumps and peristaltic hose pumps play very important roles in supplying the chemicals needed to treat waste streams and transferring the fluid to and from equipment. Key features and benefits to using diaphragm pumps, more specifically Graco diaphragm pumps, in wastewater applications include:

- Air operated diaphragm pumps are essentially explosion-proof

- Air operated diaphragm pumps can stall against pressure

- Diaphragm pumps are relatively easy to understand and service

- Large passages enable double diaphragm pumps to pump highly filled materials without short term significant wear

- Double diaphragm pumps have no packings or mechanical seals and can run dry without harm

- There are electric diaphragm pump options for applications that call for constant circulation

Contact C.H. Reed to Select the Correct Wastewater Pumping Solutions

One of the most crucial things to consider when it comes to wastewater treatment pumps is the importance of selecting the right pump/components for your applications. There are many factors that go into selecting the right pumping solutions. For example, the fluid flow and working pressure required, the viscosity and compatibility of the fluids being pumped, the distance between the supply container and the pump, the head pressure, and proper selection of the pump’s ball, seat, and diaphragm materials.

When you work with C.H. Reed, a designated Fluid-Handling Specialist will work with you to understand your specific wastewater applications and help you identify the exact pumping equipment you need to get the job done right. Additionally, C.H. Reed is an industrial pump service and repair center for most pump types, brands, and sizes. If your facility resides in the mid-Atlantic region, primarily in PA, MD, DE, VA, WV, OH, or Southern NY, C.H. Reed is your industrial fluid handling partner.

If you have any questions on pump applications for wastewater treatment in manufacturing facilities, eliminate any guesswork and contact us today.

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…