June 29, 2018

Quincy Q-Control Case Study

SHARE THIS POST

C.H. Reed recently installed 2 Quincy QGV-40 air compressors, and 2 Quincy QMD-230 desiccant air dryers for a food flavorings producer in Maryland. The compressor/dryer pairs were designed to be split into two independent systems. The customer specified that they wanted automatic rotation of lead/lag between the compressors, and automatic back-up if one of the compressors should fail. Using the technology that is built into Quincy Q-Control, the C.H. Reed service department was able to far exceed the customer’s expectations.

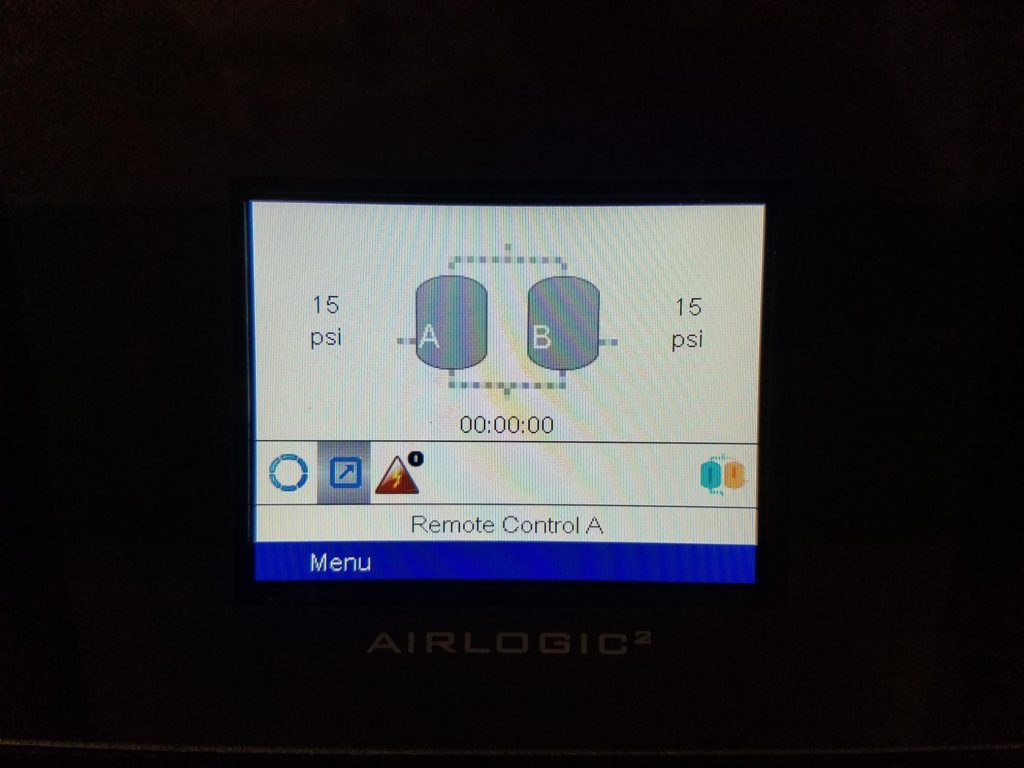

Automatic rotation and back-up: The Quincy Q-Controller comes pre-programmed with a weekly scheduler and dual pressure bands. The C.H. Reed service department took full advantage of these features to create a clean, easy to use running schedule that delivered exactly what our customer wanted. Compressor 1 was set to run at a set point of 115 psi during week 1, while compressor 2 was set to run at a set point of 105 psi during week 1. This way, Compressor 1 would carry the load of the plant, with Compressor 2 sitting in stand-by, ready to come in if Compressor 1 failed or could not maintain plant pressure. During week 2, the compressor set points switch; Compressor 1 runs at 105 psi, and Compressor 2 runs at 115 psi. The compressors switch between week 1 and week 2 automatically using the weekly scheduler.

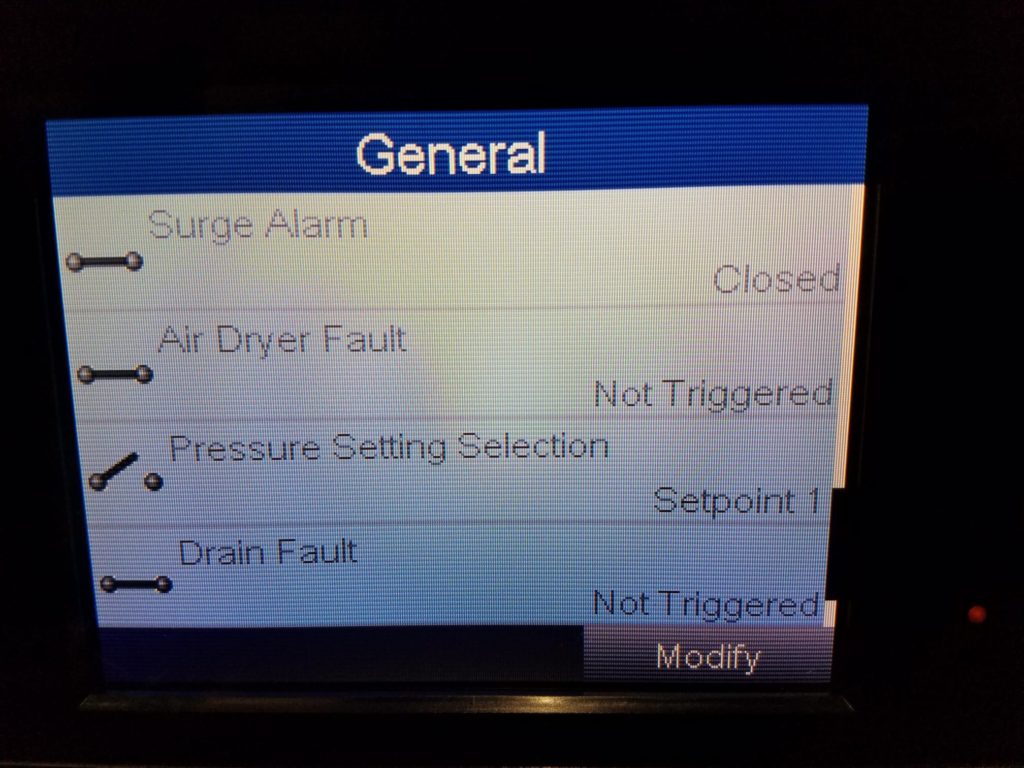

Custom Programming: The Quincy QGV air compressors come equipped with ICONS, Quincy’s remote monitoring system. The customer, and the C.H. Reed service department get SMS/E-mail alerts automatically if the air compressors fault for any reason, or if service is due on the compressors. Custom inputs to the compressor’s Q-Controller were made for monitoring the fault contacts on the QMD dryers and the zero loss drains. This allowed our customer to receive messages from ICONS if the dryers or the drains faulted out for any reason. With this type of monitoring, a dryer or drain fault can be detected and fixed before excess water builds up in the compressed air system.

Pairing the dryers with the Compressors: Because this system was designed for only one compressor to run at a time, our customer needed a way to start and stop the dryers with the compressors. Once again, the C.H. Reed service department was able to take advantage of built-in technology to make this happen. The QMD dryer has the ability to be remotely started and stopped via a digital input. An output was programmed into each QGV compressor’s Q-Controller that would trigger the remote start input on its corresponding dryer if the compressor was running. So, if Compressor 1 is running, Dryer 1 is running. If Compressor 1 is off (or in stand-by), Dryer 1 is off. The same set up was programmed into Compressor 2/Dryer 2.

Remote Pressure Sensing: In order to keep plant pressure as stable as possible, and maintain consistent pressure no matter which compressor is running in lead, both compressors needed to get their pressure readings from the same place. Instead of using the local sensors on the machines, we installed remote sensors in the system air header pipe. Quincy’s Q-Controller has the software for remote pressure sensing already loaded. The technician only needs to enable it.

Quincy’s Q-Controller comes packed with versatile, practical features that you can customize to meet your specific needs. In the above example, the Q-Controller already had everything necessary to meet our customer’s needs. No extra modules or license keys were required. The only extra hardware needed were the 2 remote pressure sensors.

Optimizing and staying connected to your compressed air system has never been easier. To learn more about Quincy Q-Control and its broad range of benefits, contact C.H. Reed today!

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…