February 26, 2020

Vacuum Pumps for Industrial Applications

SHARE THIS POST

Vacuum pumps are used by different industries around the world to remove molecules of air and other gases from a sealed or confined space; creating a vacuum to complete a wide variety of tasks. Quincy Compressor designs and manufactures various vacuum pump models to choose from, ensuring we’ll be able to help you find the right pump for your specific application.

Different Types of Industrial Vacuum Pumps

- Rotary Screw: Rotary screw vacuum pumps operate with two parallel screws inside the housing of the pump that are coordinated to turn in opposite directions; causing the compression action to occur. The gas is compressed in the direction of the pump’s discharge port.

- Rotary Vane: The rotary vane industrial vacuum pump works with a series of rotating vanes that extend and form compression cells as they rotate. These compression cells get larger to draw air in from the intake and smaller to push air out of the exhaust.

- Articulated Piston: This is a piston-operated vacuum pump that draws air in as it moves down into the cylinder. As the piston moves upwards, the air escapes through an exhaust valve. (Think of an automobile engine.)

- Claw: Claw pumps work with two rotors that turn to move air from the suction side over to the pressure side, creating a pressure disparity that compresses the air.

- Liquid Ring: These vacuum pumps work via positive displacement. A liquid ring that rotates and seals the pump’s impeller and its blades, which are rotating inside the pump casing. Liquid is sucked into the compression chamber to keep the ring stable. As the impeller rotates, it compresses air.

Each type of vacuum pump has advantages and disadvantages depending on your application, the environment the pump will be operating in, how the pump is maintained, etc. If you are unsure of what type you need, a C.H. Reed Vacuum Specialist can work with you and help you identify the best pump(s) for your needs.

Deep Dive: Quincy QSV Rotary Screw Vacuum Pumps

The Quincy QSV focuses on delivering the exact performance your application requires, at the lowest possible life cycle cost. These are ideal for applications where you need to maintain a set vacuum level.

The Quincy QSV focuses on delivering the exact performance your application requires, at the lowest possible life cycle cost. These are ideal for applications where you need to maintain a set vacuum level.

- Power: 7.5HP – 125HP

- Capacity: 230ACFM – 3023ACFM

- Minimum Inlet Pressure: 29.9” HgV

- Direct Drive / Variable Speed Drive

- Modulating Inlet Valve

- Standard NEMA motor, 3 phase, 60 hz, 460 volts

- Humid Option for Increased Water Vapor Handling Capacity

- Hot-Cool Zones

- Airlogic Monitoring System

- Small Footprint

- Air or Water-Cooled

- Optimal Oil Retention < 3 ppm

- Half the Noise Level of Comparable Vacuum Technologies

- 8,000 Hour Oil Life

- 4,000 Hour Oil Separator Life

- 10 Year Airend Warranty, 5 Year Major

Quincy QSV Benefits:

Older style vacuum pumps are extremely loud, inefficient, open machines with no brains. Secondly, they have huge oil carryover rates that waste a lot of money. There are several distinct, compelling reasons as to why the Quincy QSV sets industry performance standards compared to the competition:

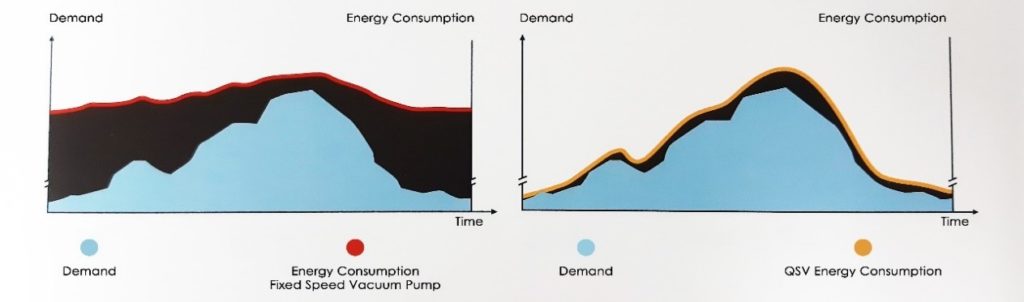

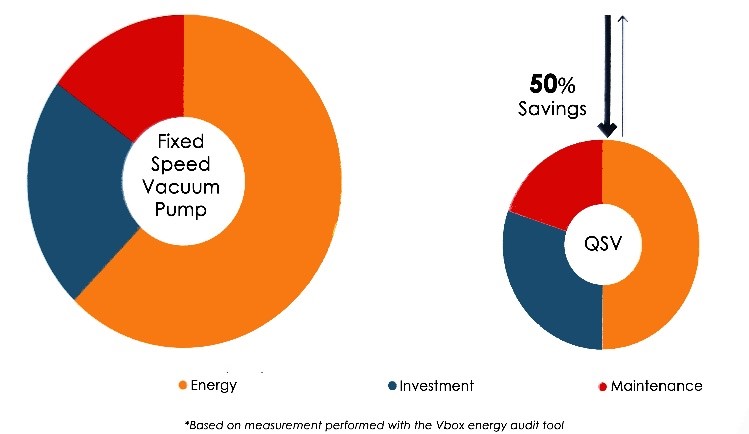

- Efficiency: When you compare delivered ACFM (actual cubic feet per minute) to input horsepower, you’ll find that the QSV outperforms the competition every time. Variable speed drive and set-point control are features not normally found on vacuum pumps. These allow you to optimize the energy you use to maintain your process vacuum level. The minimum flow will be delivered to match your required vacuum level/speed, so nothing is wasted. The QSV consumes on average 50% less energy than other fixed-speed vacuum technologies. This is achieved by startup current limitation, efficiency gain with oil-injected screw element, the variable speed drive matches and follows the demand, and the stable pressure set point. They are among the most energy-efficient oil-lubricated vacuum pumps on the market.

- Life Cycle: Quincy QSV Vacuum Pumps are designed with heavy-duty compressor bearings in a compressor service airend. This translates into extended product life and a lower total-cost-of-ownership. The oil separator is engineered for highly efficient oil coalescing with ultra-low backpressure, again saving energy. The oil separator has double the life of comparable oil-sealed vane vacuum pumps. Quincy also has a patented design that prevents filtration media to be overloaded, so they last much longer.

- Advanced Controls: Quincy’s Airlogic Monitoring System is a state-of-the-art control/monitoring system for air compressors, and now, vacuum pumps. It’s easy to use yet comprehensive. It features a 3.5” HD color display with clear pictograms, 32 language settings, LED indicators for service alarms, and showcases graphical displays of key parameters (day, week, month.) It easily provides you all the information you need to know for everyday management: alarms, safety shutdowns, maintenance schedules, operating statuses, recording of running/stopped hours, programmable timers, temp/pressure read-outs, setpoint control, remote monitoring options and much more.

- Packaging: The Quincy QSV Vacuum Pump is supplied standard with full electricals, inlet filtration, base frame, and controls. Simply connect to the system, plug it in, and go. Its space-saving design offers users one of the smallest footprints on the market, no larger than the footprint of a standard pallet. Everything you need is a single, aesthetically pleasing enclosure. A simple plug-and-play installation, if you will.

- Industry-Leading Royal Blue Warranty: The QSV Rotary Screw Vacuum Pump comes with Quincy’s Royal Blue Warranty. Given that all applicable requirements are met, the Royal Blue Warranty will cover:

- Airend – 10 Years

- Oil Separator Tanks – Five Years

- Variable Speed Drives – Five Years

- Drive Motors – Five Years

- Air & Fluid Heat Exchangers – Five Years

- Vacuum Pump – 1 Year

Typical Industry Applications for QSV Rotary Screw Vacuum Pumps

These Quincy QSV Vacuum Pumps are reliable workhorses that meet the challenging requirements of numerous diverse industries:

Holding, Lifting, and Moving Applications:

- Pick-and-place applications

- Board testing

- Pneumatic conveying

- Printing and binding

- Envelope manufacturing

- General packaging

- Woodworking

- CNC routers

Forming and Shaping Applications:

- Plastics (i.e. bathtubs, shower trays, etc.)

- Packaging materials like thermoformed parts

- Glass items such as bottles and windscreens

- Wood/lamination

Preserving Applications:

- Meat Packaging (flat, vacuum packs, controlled atmosphere packaging)

- Poultry packaging

- Modified atmosphere packaging

- Canning

- Freeze Drying

Clean Environments

- Heat treatment, nitriding, metallurgy

- Altitude simulations

- Drying and general evacuation duties

- Coating

- Surgical suction

- Laboratory systems

Vacuum Pump Solutions for the mid-Atlantic Region

C.H. Reed, Inc., headquartered in Hanover, Pennsylvania, has a sales and service footprint that covers the entire mid-Atlantic region; expanding across Pennsylvania, Maryland, Delaware, Virginia, West Virginia, Ohio, and Southern New York. With a dedicated team of Vacuum Pump Specialists and factory-trained Service Technicians, we’re ready to help you find and integrate the best comprehensive vacuum solutions for your specific needs. It simply starts with a conversation; contact us today if you have a vacuum requirement in your facility or would like to learn more about our vacuum offerings through Quincy Compressor.

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…