August 14, 2018

Automating a Paint Line

SHARE THIS POST

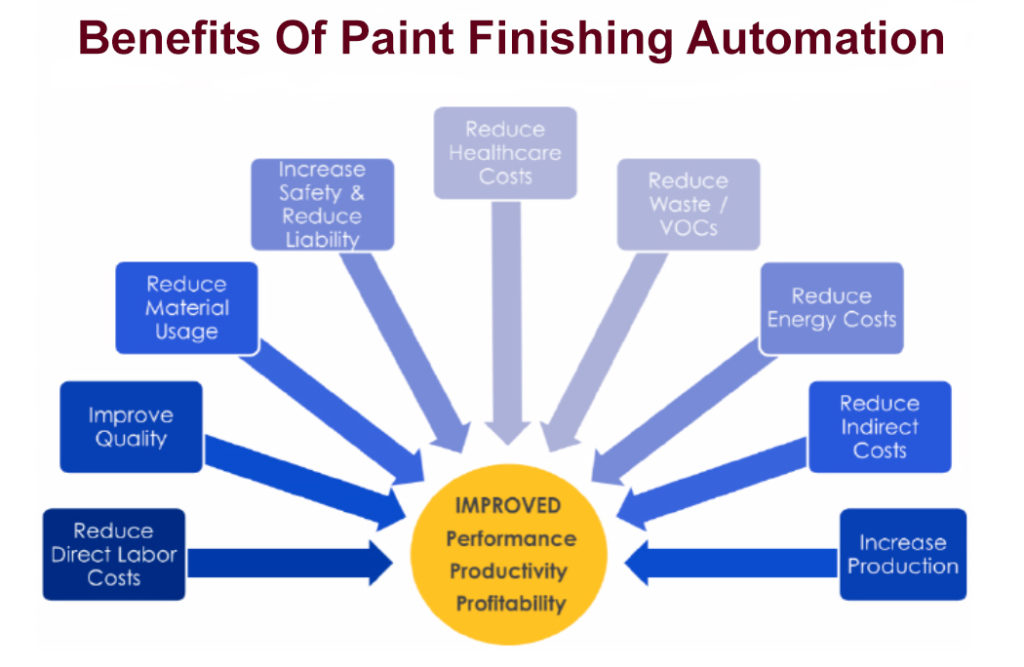

Industrial automation can be defined as the use of computers, robots, information technologies, and other control systems that handle different processes and machinery to achieve superior performance. Manufacturers around the world are streamlining their painting & finishing processes by automating their facility’s paint lines. Investing in new automation technologies for your paint line can bring many benefits that far exceed implementation costs:

- Cost Reductions

Simply put, robots can do more with less. Trimming direct labor costs, healthcare and benefits, indirect labor costs, material costs, and other costly non-value adding processes are all key factors that management focuses on when considering paint line automation. - Improved Quality

Automation can improve the quality of your finished product. Robots can accomplish different tasks with ease that are often difficult for humans to achieve manually (I.e. repeatable, precise movements). Automating your paint line also eliminates subjective decision making, variation, and operator error – all of which can happen in a manual process. - Improved Response Time

Robotics can be programmed to automatically and quickly adjust painting parameters and spray paths; letting you paint different parts faster compared to a manual change. Robots can also handle an increased volume, eliminate bottlenecks, operate 24/7, and they don’t take days off!  Reduced Waste

Reduced Waste

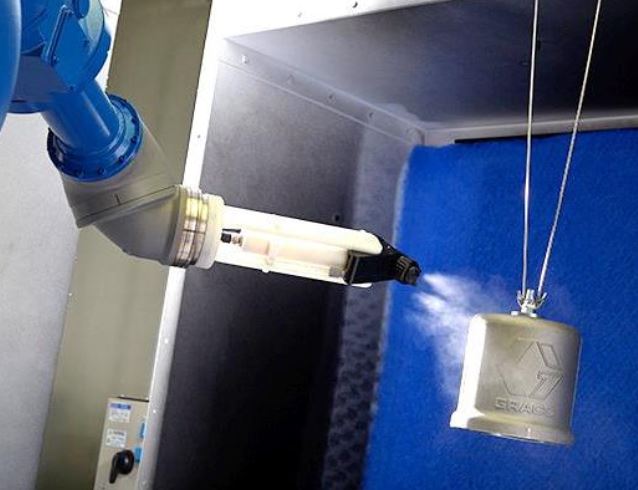

Graco, an industry leader in paint finishing and fluid dispense equipment, says that automation can reduce material consumption by 30%, thanks to the accuracy of robotics. On top of that, advanced equipment like their ProMix PD2K Proportioner (designed for accurate mix ratios and smaller flush zones) reduce disposal costs and allow for faster color changes. Another example is electrostatic paint spray guns. These spray guns produce an electric charge that is applied to liquid paint and sprayed onto grounded objects. They deliver the industry’s highest paint transfer efficiencies and highest quality finishes.- Safety

Automated paint lines remove employees from dangerous conditions and repetitive tasks. Repetitive stress claims, chemical exposure, and work related injuries are all common occurrences in the manufacturing workplace. Many people may be surprised on the true costs of avoidable occupational injuries and the impact they have on a company’s financials. Take for example, a painter develops carpal tunnel syndrome; According to OSHA’s “Safety Pays Estimator”, 1 incident of carpal tunnel has an estimated direct cost of $60,500 and an indirect cost of $66,500; resulting in a combined total of around $127,000. To put it bluntly, robots don't get injured on the job, even in the most rigorous working conditions.

Automating a paint line, however, isn’t for everyone. There are some things you need to consider when determining what parts and processes to automate. For example, high-volume parts, labor-intensive parts, or parts with similar configurations would all benefit from automation. Below are basic guidelines you should follow:

Automate Parts That:

- Have similar size / features / surfaces

- Have the same processes during painting

- Contribute to 80% of your volume and include 20% of your part numbers

- Are already organized into a manufacturing line

- Require a high amount of non-value-added labor (painter prep, repositioning, movement, etc.)

- Require precise control with zero margin for error

DON’T Automate Parts That:

- Have unique features or different processes from your other “high volume” parts

- Are difficult to fixture (unstable or difficult to align)

- An operator can accomplish the task easier and more efficient than a robot

- Have low labor content

These are simply a few recommendations to help direct you through your automation decision making process. Industrial automation technologies continue to evolve; making them more flexible, more affordable, and easier to implement than ever. As with any significant change, the benefits of automating your paint line should be carefully evaluated before you make your decision. Have a plan mapped out; before, during, and after. C.H. Reed is here to help guide you to your paint finishing goals. Connect with us and utilize our Engineered Systems Department as a resource as you embark down your automation journey.

Sources:

- Automating Your Paint Line: How to Know When You're Ready. (n.d.). Retrieved from http://www.graco.com/us/en/products/manufacturing/automation/how-to-know-when-you-are-ready.html

- Automating Your Paint Line: What Parts Should You Consider. (n.d.). Retrieved from http://www.graco.com/us/en/products/manufacturing/automation/what-parts-should-you-consider.html

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…